This test was primarily started due to recent problems with the ultra-bright Imalent SR32. During the passaround of this light in the German flashlight forum, two XHP50.3 HI LEDs were damaged for the second time (after the first repair which consisted in replacing the whole lamp head).

For this reason, I decided to quickly test the XHP50.3 HI to at least determine the maximum possible power and to check to what extent the LED itself could have something to do with these defects that have already occurred more often. I have tested here the 6 V version, in a variant with 90 CRI and 4500 K, because I usually only buy LEDs for testing that I eventually want to install in my own lamps and therefore place little value on low-CRI variants with the highest possible Bin, but in general the electrical performance should also apply to the Low-CRI variants of this LED type.

Tj 85 °C, If 1,400 mA

Order code: XHP50D-H0-0000-0D0UH245G

Typ: multi-die

Binning: H2 (900 lm +/- 7 %)

Color kit: 45G (3-step 4500 K)

CRI: min. 90

Rated voltage: typ. 5.6 V (max. 6.2 V)

Maximum rated current: 3,000 mA

Maximum pulse current: N/A

Viewing angle: 120°

Thermal resistance: 0.4 K/W

Max. temperature Tj: max. 150 °C

Datasheet (newest version, Cree)

The XHP50.3 HI is a LED without dome (domeless). The 4 LED chips are clearly visible. In the 6 V, 2 of them are connected in series and 2 in parallel (2S2P), in the 12 V configuration 4S.

Noticeable is the luminous area on the top left, which seems to be somewhat “offset”. However, this should not affect the operation of the LED itself. Both my samples show this anomaly in the same way.

This variant is similar to the XHP35/.2 LEDs, which also come with a similar luminous surface, but only in XP format and with 12 V nominal voltage.

The footprint in the 5050 format (external dimensions 5.00 x 5.00 mm) fits on XM boards without any problems, and the symmetrical package means that commercially available XM centering aids can be used. When using commercially available XM boards (such as Noctigon XM20), the LED is in most cases operated in the 6 V configuration, which is also the usualing wiring in flashlights.

The small gray box on the thermal pad indicates the cathode.

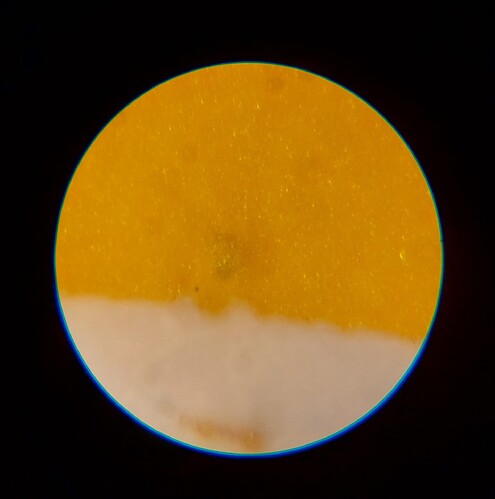

At low operating current, a faint glow around the illuminated area is visible, indicating lateral radiation from the LED chips, similar to the older XP-L2 or the XHP variants XHP50.2/70.2. In the test of these LEDs it was determined, that this radiation was the reason for relatively strongly visible color distortions around a strongly bluish spot.

In contrast to the earlier LED platform, this effect is less pronounced in the XHP50.3, which improves the light image. The LED is quite usable in OP reflectors, although there are still slight color shifts between spot and corona as well as (sometimes) spill. For most applications this is not a problem, if this LED is used with a frosted or heavily textured TIR optic, the color shift is no longer noticeable.

The relatively suddenly reached maximum (12.8 A @ 3891 lm @ 7.72 V) and especially the rapid drop in luminous flux when exceeding this is striking. The Vf is relatively high, but Cree also specifies a relatively generous range up to 6.2 V @ 1.4 A (typ. 5.6 V), which could possibly indicate strong outliers in individual samples.

For a sample with 5.6 V @ 1.4 A, a Vf of below 7.2 V at maximum current is quite realistic.

At the maximum current of 12.8 A, an efficiency of only 39.4 lm/W was achieved; a value that is already sometimes exceeded by special high-power halogen lamps (mostly used for projectors or studio spotlights).

There are hardly any surprises in the comparison chart. Based on the performance compared to XHP70 LEDs, I suspect that primarily the limited heat dissipation area of the XM footprint limits the maximum achievable performance with the XHP50.3, at least if the thermal resistance of only 0.4 K/W actually applies to series samples.

However, something else happened that could explain the LED failures in the Imalent SR32 mentioned at the beginning - or at least gives a hint: the LED tested here has been destroyed while testing. This normally happens very rarely or has to be deliberately done, as it is the case in so-called “crash tests”.

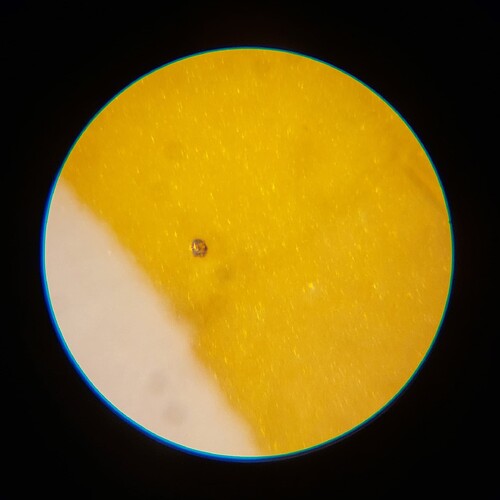

After the first run (determining the maximum of the LED luminous flux in regular way) the luminous area looked like this:

The maximum current was only maintained for a few seconds, in the range If > 8000 mA this sample was in operation for a maximum of two minutes.

This is indeed an error pattern which already circulated in pictures, also in connection with the Imalent SR32. It should be noted that NO flux residues or similar were found on the light area. The luminous surface was absolutely clean before the start of the test, this was checked before the test, moreover, I never touch the luminous surface with bare hands. In my case, this damage only occurred in the highest power range (above 9000 mA).

It is interesting that this dark brown spot appears on almost all damaged LEDs at the same spot on the LED chip, almost as if a local hotspot was created there, possibly due to uneven heat dissipation. The position of the individual LED chip on the substrate does not seem to play a role. It is particularly noticeable in this image of a review video of the SR32 (min. 26:17).

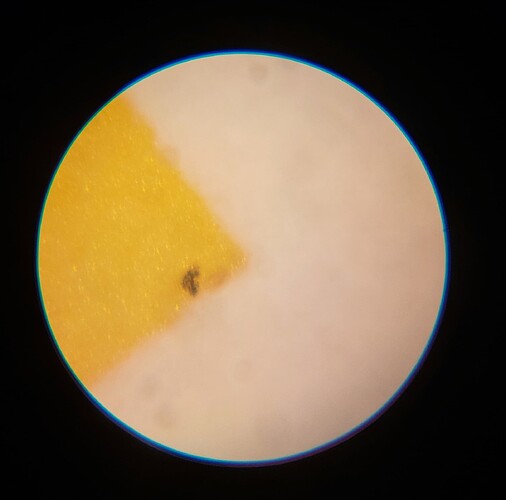

During the determination of the luminance, the emitter was finally completely destroyed - something that was to be expected considering the earlier damage, although the extent of the damage is nevertheless enormous:

The luminous surface is pretty much burnt in the middle. Of course, this is the extreme case, because in this case the LED was driven to almost 11 A for a second time (after that I immediately stopped the test), but the damage pattern is very similar to the damaged LEDs in the Imalent SR32, where the same approaches are visible.

To get more in depth with the cause of this failure, I took a closer look at the XHP50.3 HI LED tested here and damaged in the process.

First, I tried to get the black undefinable mass from the luminous surface. Interestingly, there was still undamaged phosphor underneath. This alone is a sign that we are not necessarily dealing with an overheating of the LED chip. At least the burn did not extend down to the LED chip, which should confirm the good heat dissipation of the LED chips – the source of the heat is likely not coming from the LED chips itself.

I can’t exactly explain why the LED was so catastrophically damaged here. It seemed as if the silicone was burned by too high temperatures during massive overcurrent. Only - by what? There were no dust or flux residues on my LED. I would have seen these, especially on the smooth white surface of a HI-LED.

Considering the de facto identical damage of the LEDs in the Imalent SR32, this cause could be identical. At least a burn of the silicone by overheating of the LED chips is excluded, rather I assume that the extreme light flow in the silicone itself was the cause for a massive heat rise.

Whereby there are more interesting things like the already documented “dark spots” at almost the same places on the LED chips. This dark spot also occurred in my case, although it was a bit more visible. Starting from this dark spot, the massive burn may have originated at the end and then spread further.

One theory could be that the silicone is thicker or less permeable to light at these points due to some circumstances and that this creates local tiny hotspots, which burn the silicone starting from a certain luminous flux/operating current. Since dark residues are created by the combustion and these in turn heat up massively due to the extreme luminous flux, they burn further silicone, which again creates dark residues and so on.

This could explain the error pattern so far, but the actual cause for the dark spots remains unclear.

A more yellowish discoloration of the phosphor is noticeable at the spot where the dark spot was created later. These discolorations can be seen more or less symmetrically at the same places of the respective LED chips, pretty much at the same places that can also be seen here (screenshot YT video review SR32), partly on several LED chips of one emitter.

For me, this speaks against the contamination of the LED surface by flux splashes or darker dust. In such a case, the dark burn marks would have to appear more or less at random places, since the distribution of dust or flux is also subject to chance. In addition, when LEDs are reflowed - especially on an industrial scale, as is likely to be the case at Imalent - so-called PCB stencils are used.

These are thin stainless steel sheets with precisely milled openings in order to apply solder paste to the PCB as precisely as possible and according to very precise manufacturer specifications in precisely defined quantities. Among other things, these manufacturer recommendations are also designed with regard to avoidable contamination by flux, which makes me think that this cause is very unlikely in the case of the SR32’s defects.

I only have one XHP50.3 HI left in stock and would hate to use it for another test, as it was originally intended to be, or still is, for a lamp conversion.

However, it seems to me that there is not “the one” cause for this error pattern here. What is striking here, as mentioned, is the relatively constant error pattern with very similar location of the cause of the error (dark spot).

This is how the XHP50.3 looks without silicone encapsulation and phosphor. The four luminous surfaces are conctated via flip chip mounting on the underside, there are no bonding wires.

At first glance, the LED chips did not suffer any damage. At least no (heat-related) damage is visible.

The chips light up without any problems at a few mA. The bright appearing lines between the chips are phosphors, which I could not remove.

And here also confirms what I already suspected: the LED chips also emit light to the side.

This explains the weak glow even directly next to the luminous surface. This effect was first noticed with the XP-G3 and XP-L2 LEDs a few years ago.

In general I strongly recommend being very careful with overcurrenting the XHP50.3 HD and HI (both LEDs differ only in the applied dome) to extreme levels and generally advise against it due to the damage pattern that occurred. Presumably, the series dispersion also plays a decisive role at which current and which temperatures the failure shown above can occur.

To be sure what the XHP50.3 HI can really withstand and what damage would look like if the LED chips overheated, I ran an extreme temperature test.

Before that, however, I let the LED run continuously for fifteen minutes at 21 A (power supply maxed out) and 8.711 V Vf (power: 182 W!) with as perfect cooling as possible. This already showed the robustness of the emitter, because obvious damage was hardly visible afterwards:

Only a small burned area can be seen between the two lower luminous surfaces. However, this did not affect the function of the LED chips. Possibly, this area comes from the burning of the silicone left in the small gap between the LED chips or other foreign objects.

The overtemperature test was performed up to a temperature of 280 degrees, which was monitored with a thermal imaging camera. (Note: Tjmax XHP50.3: 150 °C).

Even at 280 °C the chips still glow! (Snapshot from video recording)

Everything is already smoking here, including the LED board used in the test. Whereby here a LED chip is close to failure, on the other hand the robustness of today’s LEDs in general is very impressive, as these operating conditions are far above what the manufacturers generally state as the maximum temperature of the LED chips.

The result after the extreme test:

The substrate is darkly discolored, and some of the LED chips were very easy to remove (they were still attached to the substrate however). Any damage to the chips was only from the removal process. The chips themselves were still in place before removal.

In summary, from the LED chip side the XHP50.3 is an extremely robust emitter that can withstand even 20 A. In this regard, it is in good company with the XP-L2, which withstood nearly 15 A before destruction. So the failures in the Imalent SR32 have likely nothing to do with overheating of the LED chips, but are due to the silicone or the contamination of the surface (although this is rather unlikely, as already explained).

The light color of the XHP50.3 HI tested here is okay. The duv is a bit higher, but subjectively the light is usable without slipping too much into hues.

With an Ra of 92 and R9 of 66, this is one of Cree’s much better LEDs when it comes to color rendering. However, the XHP50.3 doesn’t stand a chance against a Nichia even in the 90 CRI variant; the duv of 0.0053 is immediately noticeable in direct comparison; the light appears greenish and the colors are accordingly not as saturated as it is the case with the Nichia and also the LH351D.

I could not perform more precise tests due to the destruction of the emitter, my second sample may deviate significantly from the above values despite tighter 3-step binning.

Pro

- compatibility with XM accessories given

- relatively good tint and CRI values

- high power and luminous flux

Neutral

- relatively high Vf

Contra

- destruction of the emitter clearly before achievable luminous flux maximum

- operation of the emitter only with nominal data or very careful overcurrent recommended

I hope this review was helpful for your next moddings. ![]()

Greetings, Dominik