I like to use Judco Pushbutton switches when I can. The reason is because they make switches that take up to 10 amps and they are affordable. One other reason is because the contacts are copper instead of plated tin.

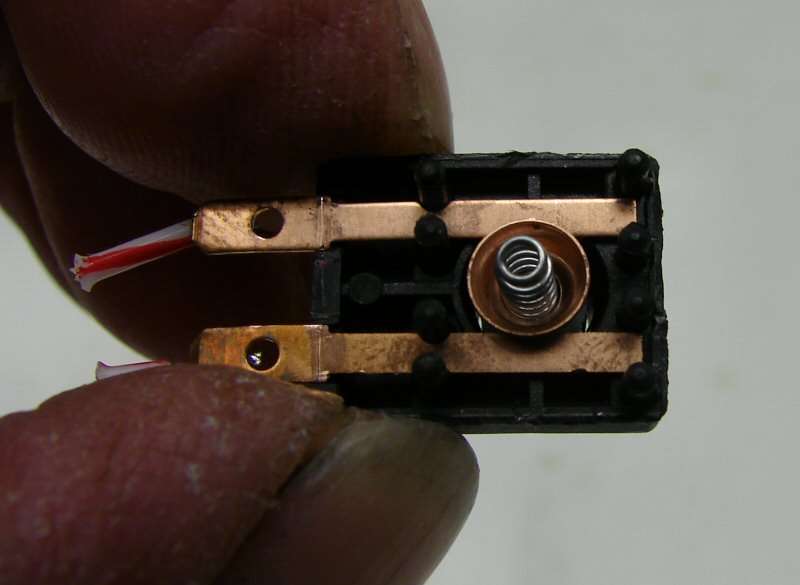

Here is the switch opened up. You can see the copper contacts and horn.

Here are the components.

The only problem sometimes, is the offset position of the push button. I would rather it was centered in the body, or if the body was square somehow.....

Solution: Use a hacksaw to cut off the extension of the housing just past where the pins are, that hold the housing together. This leaves us with a more centered pushbutton.

Here, I am putting it back together. I have put the housing in the vise, so it is flush. That way, when I put in the contacts, they stay in place while I get the horn in.

Now I have a 13mm x 13mm square Judco switch and with a little rounding of the corners, it will fit in a half inch copper coupling, for an upcoming project. I will use AA or epoxy, to seal the end where I cut off. That way it strengthens the contacts where they extend out.

I did this post at work, so I can't even see the photos myself. I hope it comes out ok, or I will have to fix it at home tonight.