I want to get here tips from experienced people, also some how to do videos and other guide tips

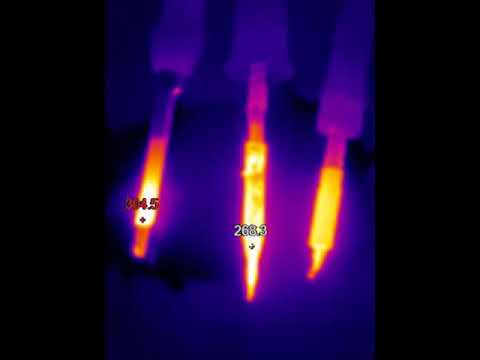

You can solder all day on the boards without stripping pads if you solder with 280-295 degree Celsius and leaded solder,

what kills pads is too much heat, unregulated irons get easily to 400°C and more, they destroy the glue between PCB and copper

.

generally soldering SMD with unregulated iron is a really bad idea, you have to be very fast so the pad does not overheat

better invest like 45$ for an iron or mini station with T12 tips or other Hakko clones

Station

HW version should be 2.1S

https://de.aliexpress.com/item/32837522724.html

newest revision

https://de.aliexpress.com/item/32950981884.html

v2.00 is quite cheaper but it has some flaws

Mobile

(needs a 19-24V PSU like Laptop ones, more voltage more power)

https://www.banggood.com/MINI-TS100-Digital-OLED-Programmable-Interface-DC-5525-Soldering-Iron-Station-Built-in-STM32-Chip-p-984214.html

T12 tips

pro:

- you have in each tip the heating element, so if it dies you need no expensive replacement than other stations have

con:

- variation between tips in the temperature reading

preferred tip shapes for 0603 soldering:

BCF1, D16

for general soldering:

D24

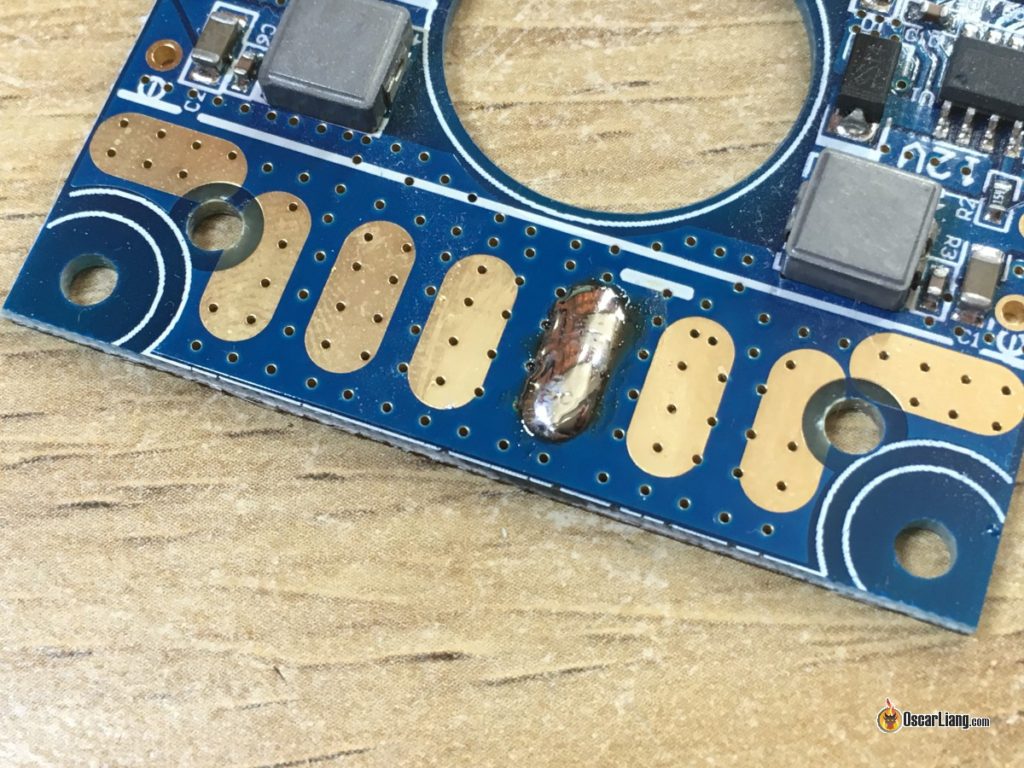

for MCPCBs:

D52, C4

Pre tin pads and wires is a good solution, especially with unregulated, just keep the solder time as short as possible

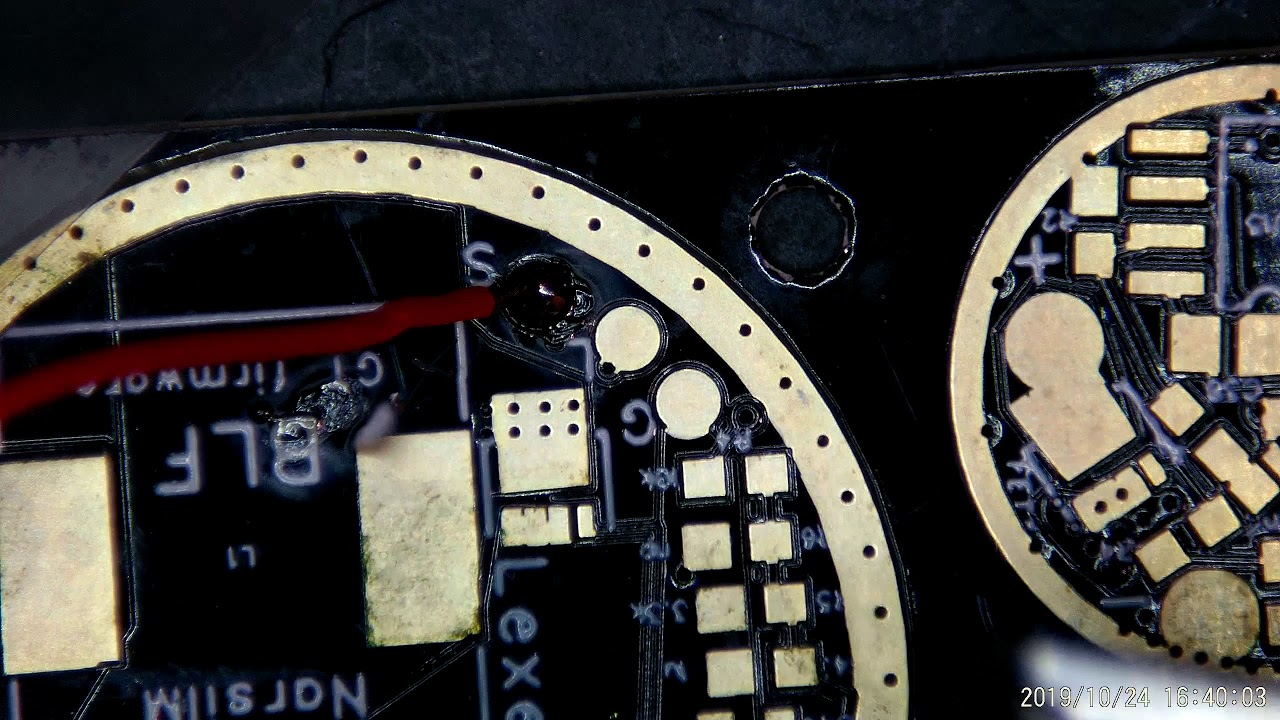

The pads on my newer designs are reinforced with a via so a melted glue by too hot iron won’t lift it, then too much mechanical force removes the pad

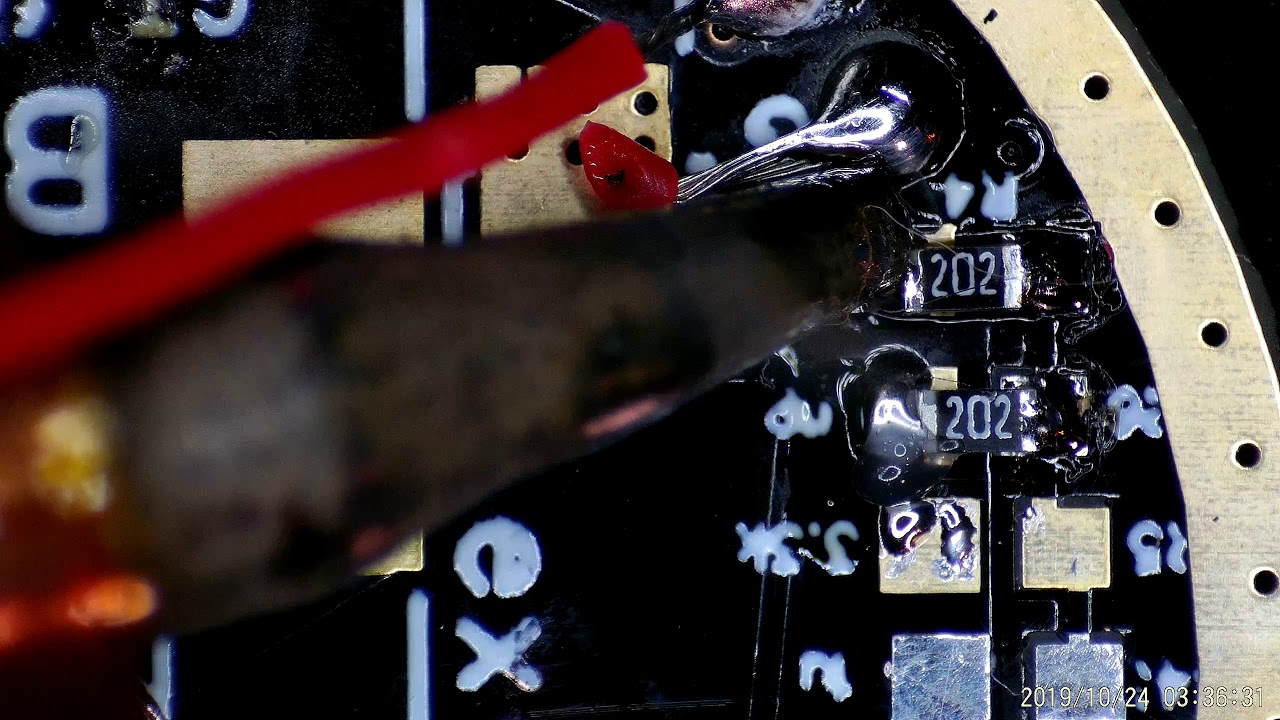

To remove an unwanted bridge I use a tip which is flat on the front, so I can simply push the solder to one pad and the bridge is gone

using rosin core copper braid to remove unwanted solder bridges with an unregulated iron is a bad idea

This is the most effective Weller tip shape I use in 100% of the cases if not more heat is needed like on MCPCBs, you can solder even 0402s even if the tip seems gigantic compared to the resistor

The flat end is so much better to solder SMD, if you rotate it you have an area that easily makes contact with both ends of a 0603 resistor

To remove a resistor I usually add carefully some solder then flip the my tip by 180° so I can use the longer side melting both ends

too bad T12 tips are not available in such an angled design

.

Flux and solder wire

A main reason why soldering can be hard is the quality of the solder wire or flux you use, usually flux helps to remove oxidation and also conducts a little heat

Quality solder wire is a key for low temperature soldering,

I did once the error to buy some cheap 0.3mm leaded from China but that stuff was the least shit did not solder at all at my usual 295°C

good solder wire is not cheap

Generally rosin core SN62Pb36Ag2 is one of the best compounds you can find

reflow soldering you need a flux that does not burn like rosin core

Amtech NC-559-ASM-UV is a good one,

but with many of them a good ventilation or solder steam filtering system is good

If you do a lot of soldering and want precise amounts of flux or different fluids like glue/thermal paste applies its best to get a proper dispensing solution