Introduction of an updated method of testing UV-leds.

I make a point of posting my test methods very thoroughly because the equipment that I use never looks like a slick designed box that makes you automatically trust in what it is doing, but it usually is a messy combination of loose (but well-chosen) components, carefully bought, found in the kitchen drawer or scavenged from other equipment. That does not imply that it works less well than expensive manufactured equipment, it may work less well, just as well, or - who knows - better.

Measuring the output of UV-leds can not reliably be done with a luxmeter because if your luxmeter does a good job, it does not pick up any UV. And if you own a cheap luxmeter that does pick up UV, the detector's sensitivity probably is on a a steep slope for 360-400nm, making the read-out very sensitive for peak wavelength and spectral profile. And I fear the UV will cause damage to the delicate and expensive optical filter that is in front of my luxmeter detector. The solution could be using a radiometer, but those have their own pitfalls (like, again, large sensitivity differences in the 360-400nm region), apart from that they are expensive and I do not own one.

My way of measuring UV-leds, forced by not owning a radiometer, has been measuring radiometric output indirectly, by inducing fluorescence in photocopier paper (which absorbs a broad band of radiation from blue light to deep into UV) and measuring the resulting blue light with a common luxmeter. Having read into other methods of measuring UV-leds, this even circumvents some problems and errors that other methods have (like fluorescence of the integrating sphere coating). But of course it introduces errors too, and I'm not equiped to measure or estimate them all. The desired goal of this fluorescence method is: the number of blue photons (which I can measure well) should be a decent measure of the radiant power of the led (which I can not directly measure). There's a number of assumptions in this principle: 1) the radiometric power/blue fluorescence ratio does not vary with wavelength (I can not measure that), 2) the fluorescent substance responds to the UV-illumination in a lineair way, i.e. is far from the saturated state (can be measured but it is difficult to distuinguish from bleaching), 3) the fluorescent does not bleach (nope, copier paper at least does bleach!).

One and a half year ago I devised my latest test method for UV-leds (link), which was already method #3, but I was never very happy with it, mainly because the used photocopier paper bleaches significantly: when after a led test the paper was illuminated with a uniform UV-source you could see that the area used for the test was a little bit darker, indicating that at least the latest numbers in the led test are too low. Also not every sheet of paper showed the same amount of fluorescence, even within a single sheet there is usually a slight variation measurable, so I had to calibrate each piece of paper before a test.

The solution was to find a source of UV-fluorescence that does not bleach. What I remembered from working (in a distant past) in a lab that worked extensively with fluoresecent dies, is that basically every fluorescent substance shows bleaching (=the absorbed energy from photons may cause a chemical reaction of the die molecule which converts them into a non-fluorescent compound, so less and less fluorescent molecules are leftover). But thinking of that, I could imagine one substance that may not show bleaching at all: vaseline glas (other names: uranium glass, Anna-green glass), which is glass that shows some UV-fluorescence caused by a few percent uranium in the glass-matrix (which gives the glass its distinct green glow in daylight). I could not think of a way that the uranium in this glass could undergo a chemical reaction easily and an old collegue of mine that I consulted about this agreed with me. So off I went searching for vintage glassware (vaseline glass was popular at the beginning of the 20th century) and I found a plate with a suitable flat center that (with the edges smashed off, I did not tell the previous owner that) could serve well enough as a piece of measuring equipment :D .

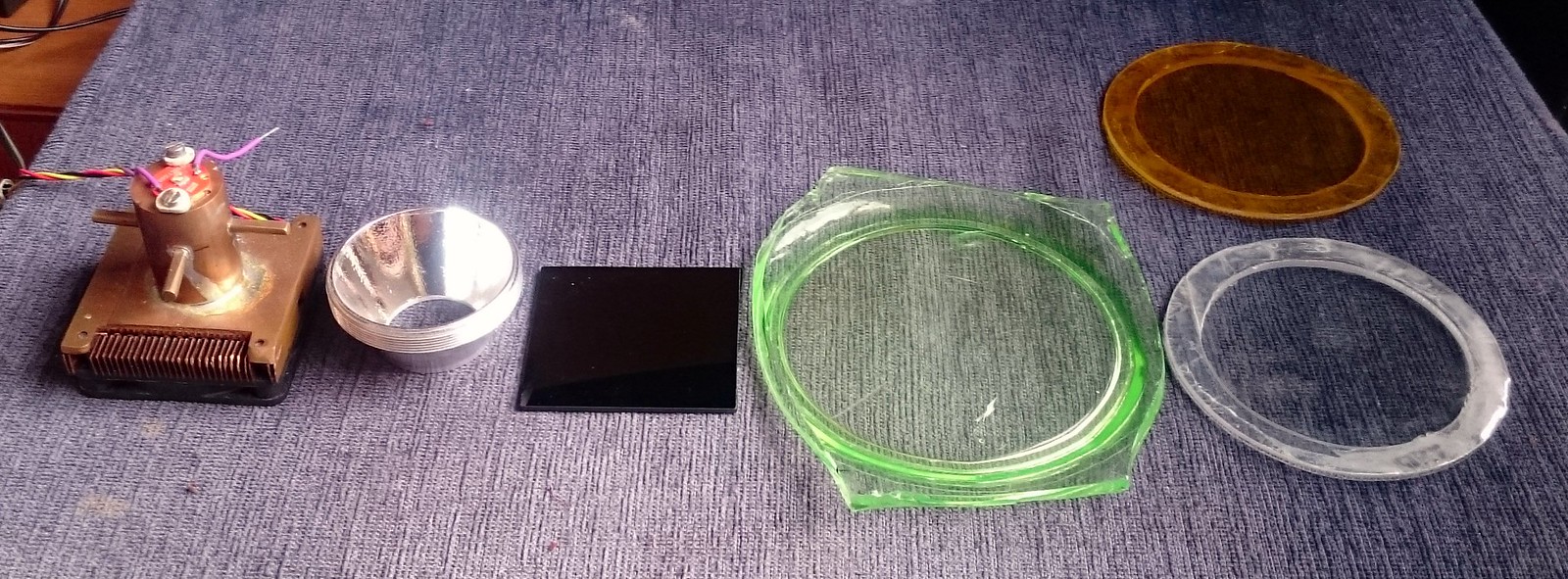

So together with some other finetuning compared to method #3, here's method #4. And I do not intend to change the method any further in the future. The picture below shows the parts, that during the measurements are stacked on top of each other over the 80mm hole of my integrating sphere.

From left to right (=from top to bottom in the stack)

- my usual cooled copper mount for testing leds

- a reflector with the bottom sawed off so that it fits the ledmount (reflector facing down), this is to make sure that as much of the light of the led as possible is directed downward, and enters the fluorescent glass. It should make the set-up quite independent of beam-profile, and some simple tests including shining a narrow UV-source down the reflector in various angles proved that to be true.

- a sheet of ZWB2 filter. This removes any visible light that the led produces (which will add to the light measured in the integrating sphere but does not contribute to the UV-power that you are trying to measure), as well as favour leds that truly peak at 365nm, because the filter has its transmission peak at 365nm.

- A flat-ish piece of vaseline glass, this will convert (a portion of) the UV-radiation into visible green light. It has scratches and slight irregularites, but because quite a surface is used the fluorescence that enters the sphere is pretty consistent.

- a sheet of LEE 226 filter (glued in a round plastic frame). This very effectively removes the remaining UV so that no UV enters the sphere (and then may damage the luxmeter) while transmitting the green light. Also a yellow filter can be seen that can be used for measuring 385nm and 400nm leds (without the ZWB2 filter in the stack).

So this all goes on top of my (messy ![]() ) sphere (auxilliary light switched on for picture):

) sphere (auxilliary light switched on for picture):

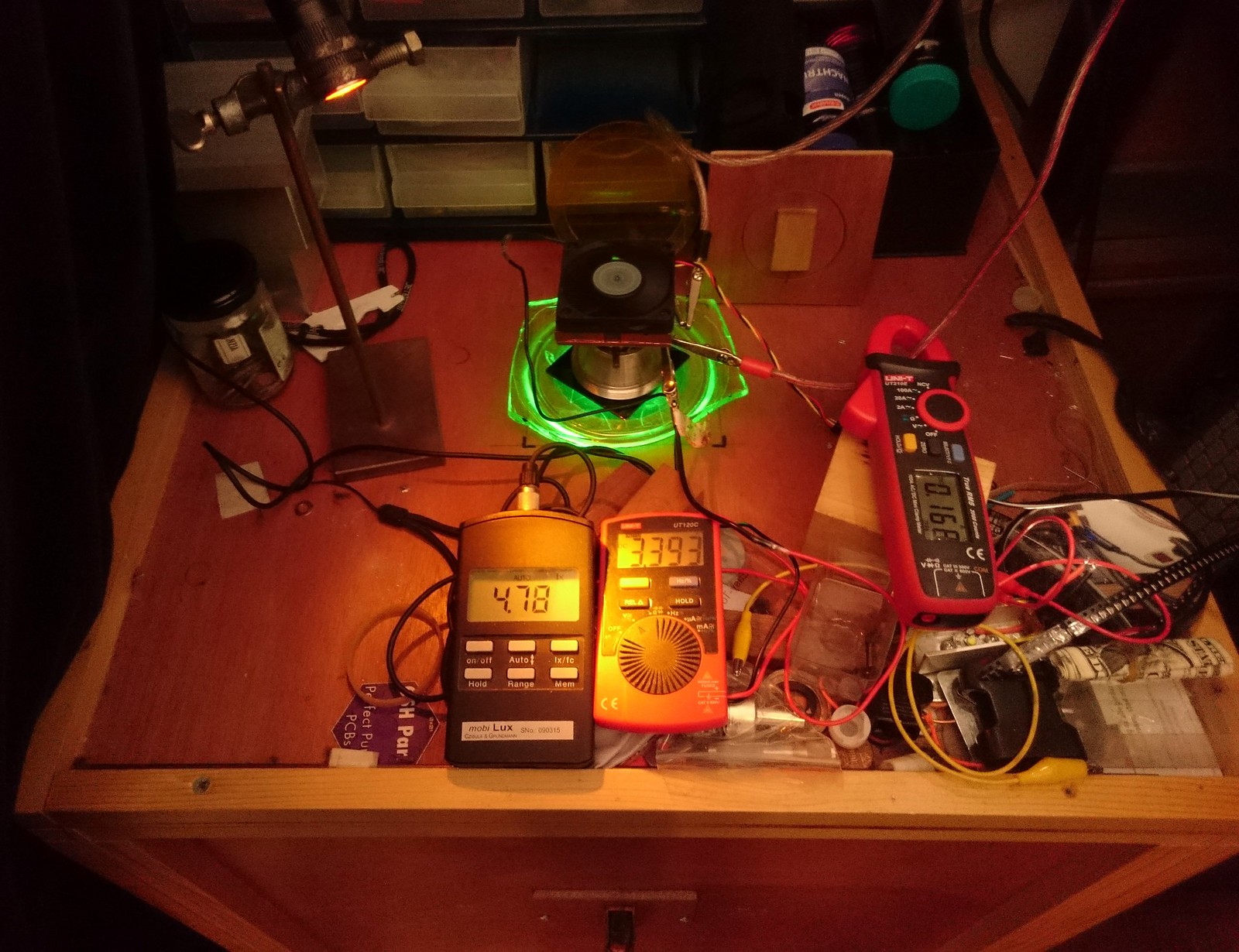

And during a test, it looks like this:

The three meters are my luxmeter, the voltage of the led, and the current through the led. The power supply can not be seen.

The tests.

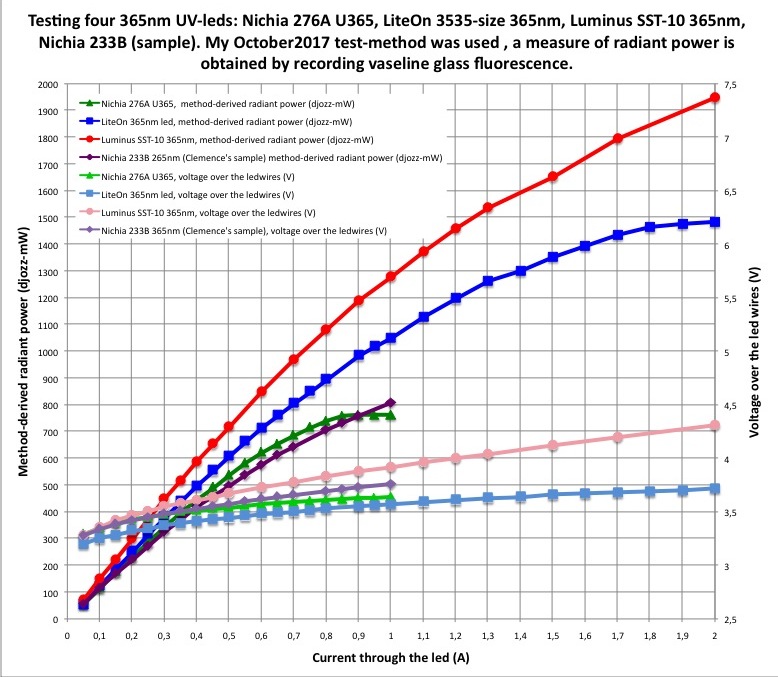

One of the goals was finally getting a calibration of the measurements so that I can tell the output of 365nm leds in milliWatts, and so I did 4 tests on different leds that have a datasheet that gives output specifications, two of the four I have measured before : a Nichia 276A U365, the LiteOn 3535 365nm led, a Luminus SST-10 365nm led, and a nichia 233B 365nm led.

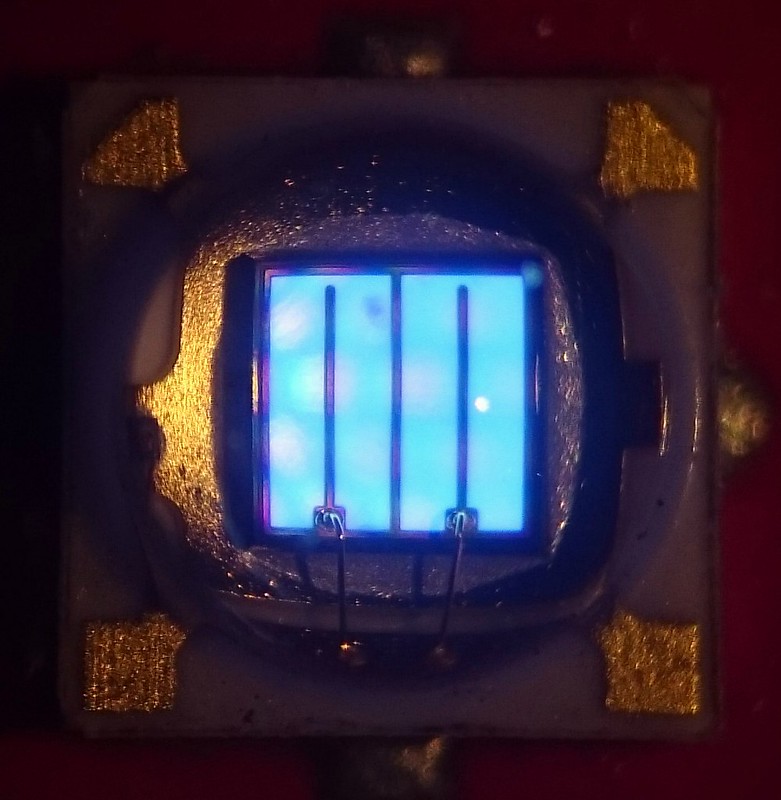

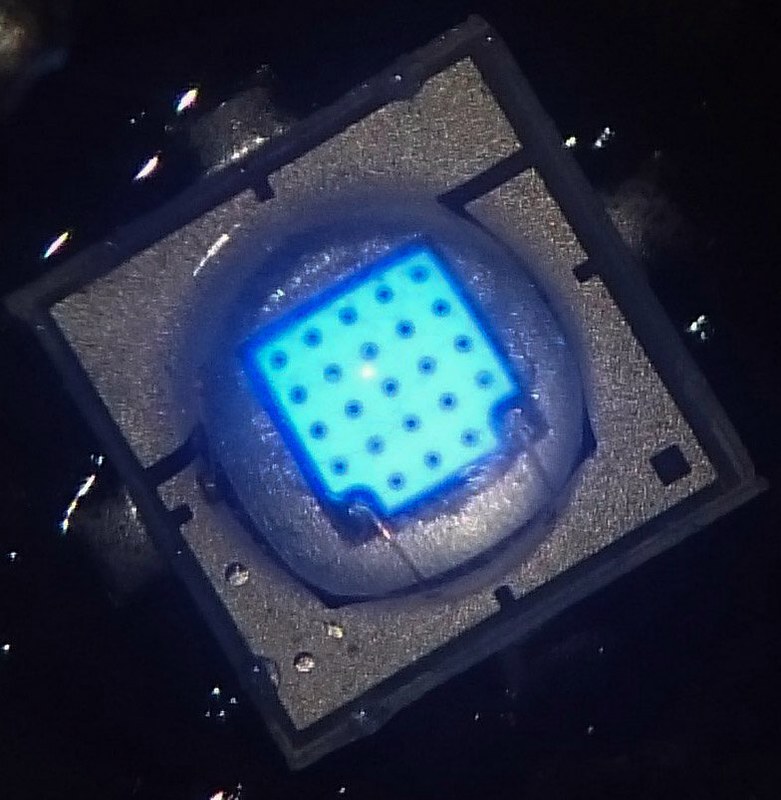

LiteOn 365nm (new type compared to previous test)

LiteOn 365nm (new type compared to previous test)

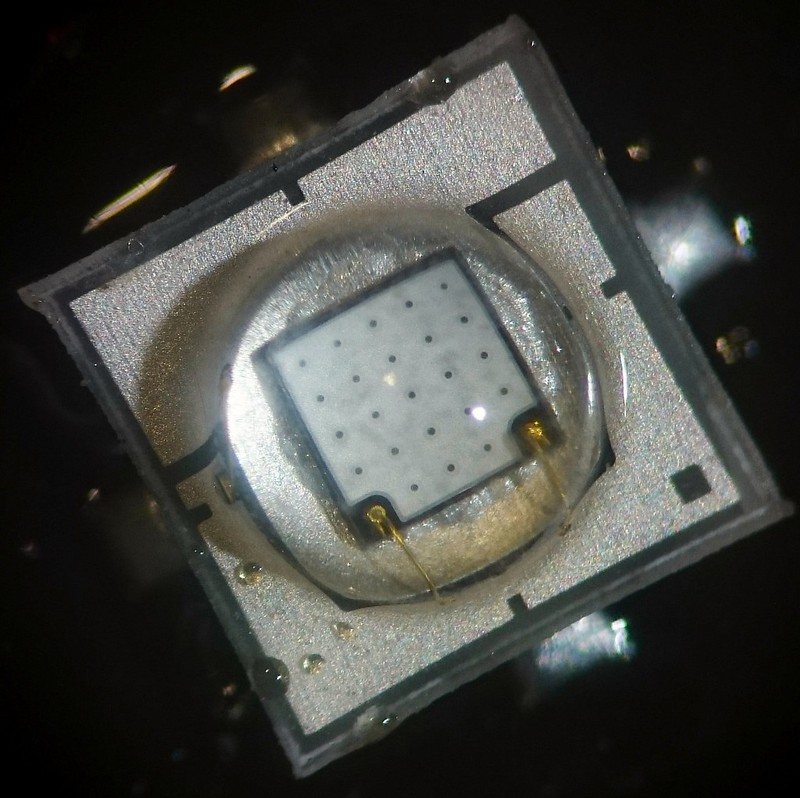

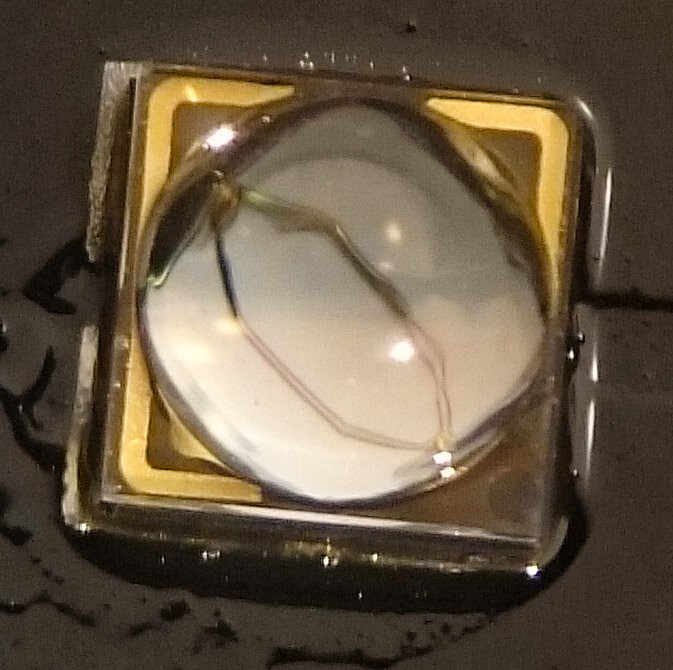

Luminus SST-10 365nm

Luminus SST-10 365nm

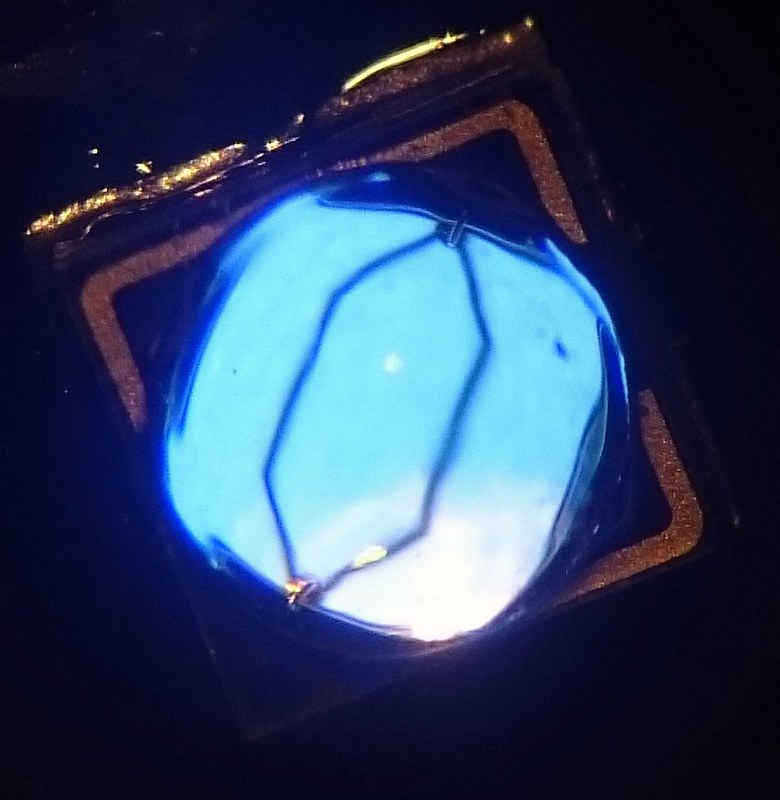

Nichia 233B 365nm

Nichia 233B 365nm

(the 276A is pictured in several other tests)

I measure the leds in my usual way, I test one bare led, cooled very well, starting at low current and at each increasing current setting letting the led settle for a moment before recording the numbers. What is typical for 365nm leds is that upon each current increase the initial output shows some gradual (slow) dropping, I think it is a temperature effect in the die. Blue leds (and thus white leds) hardly show this but I know that red leds are also very sensitive to temperature.

The LiteOn led and the SST-10 led were tested on a DTP-copper board, the two Nichia's were tested on my custom N.119 board (ok quality but non-DTP).

I took the results for these 4 leds and compared them to their respective datasheets, hoping that there would be a unifying multiplier for my test method that worked for all of them. Of course I was not so lucky, if I was to follow the datasheets these would be the multiplier (converting my integrating sphere read-out to mW) for the 4 leds:

Nichia 276A: times 60

LiteOn 3535 365nm: times 45

Luminus SST-10 365nm: times 41

Nichia 233B 365nm: times 74

A couple of options to explain the large variation:

1) my method wobbles. I do not think so, for example I re-measured the 276A led and got close to the same results, and I do not see reason why it would vary so much (I expect a few percent variation, but not 80).

2) the (some) datasheets are untrue. Could be, I don't know

3) some of the particular leds that I measured are damaged and do not perform according to their datasheet. A possibility: the 276A was salvaged from a Convoy UV flashlight, I have no idea how and at which temperature it was reflowed before. And I asked Clemence about the 233B, that I received as a present from him, and he said they were samples of the brand new leds he got from Nichia and could very well imagine that he received some rejects.

So I took the liberty to ignore the results for the two Nichia leds, while the other two were close enough together to accept, and decided to define the SST-10 multiplier ( x41 ) as my standard calibration for this method: the '365nm djozz-mW' ![]() , whatever that unit is worth in the real world.

, whatever that unit is worth in the real world.

Here are the results for the 4 leds, take into consideration that the 276A and 233B may be damaged leds.

What can be seen?

- the nichia 233B sample led that I tested, if my calibration is anywhere near correct, nowhere meets the specified 1400Mw at 1A, but I assume that the (expensive!) versions currently on sale do meet it, Nichia is not a shady company AFAIK

- the liteOn led still is a great led, and cheap. It does show some visible stray light (way more than the Nichia's) but in flashlight use that can be easily filtered out by a ZWB2 filter.

- The Nichia 276A led in the test does not perform to specs either, possibly because of a careless reflow session in the Convoy flashlight it was in before.

- The SST-10 is the winner here, not much visible stray light (observed by me but not shown in this post) and great output, possibly over 2000mW when current is over 2A (not measured). The voltage though is pretty high, direct drive on a single li-ion cell the current will not pass 1.2A and 1500mW. This can also be an advantage: you can use any popular direct driver, like the BLF-A6 driver.

Conclusions:

I really like the method as it is now, but it still has to prove itself over time.

And get the SST-10 led, it is great!

Thanks for reading!