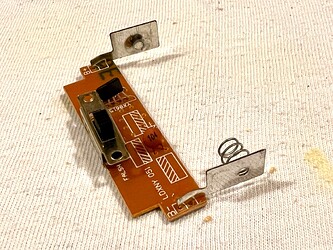

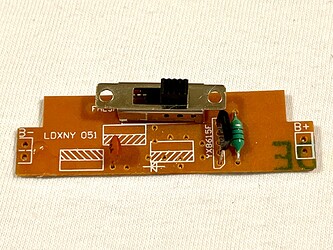

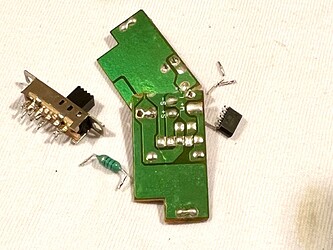

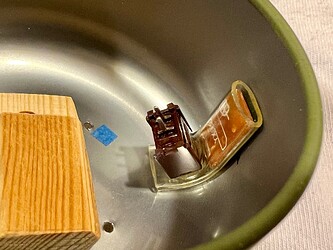

For the ancillary light, I was able to use the circuit board that I salvaged the battery spring and contact from.

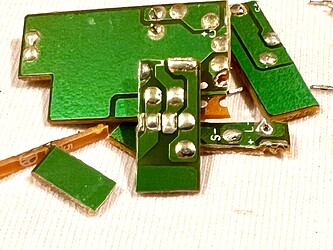

I removed the components using a soldering iron and a wire cutter to cut out the area that I needed.

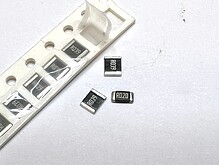

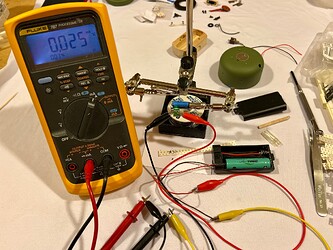

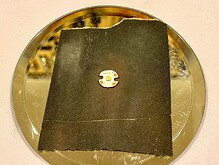

I soldered a green 0805 SMD LED onto the board. Then experimented with different value resistors to get the brightness and current I wanted. I ended up using a 75K ohm resistor which draws 0.025mA at 4.1v. So with the older protected 14500 ZebraLight battery that will be using, it will last around 3 years.

Next I was trying to figure out how to attach the light to the container. I initially was going to tape it to the container using Kapton tape, but wanted something more secure. I also thought about drilling a hole into the circuit board and screwing it to the container.

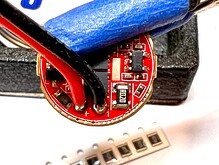

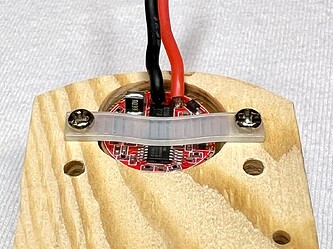

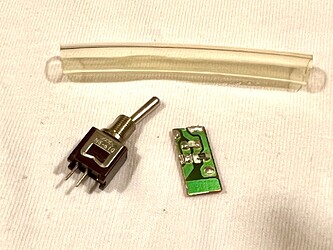

Then I came up with a pretty clever idea (as least I think it was)! I squeezed the board into a plastic hose, drilled a hole into the hose, and attach it directly to the switch.

The hose will also act as a washer to keep the switch in place when attached to the container.

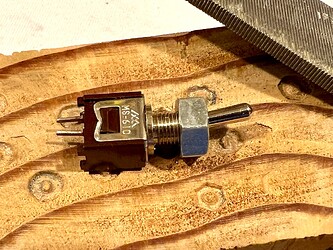

Next was attaching the main switch. I wasn’t sure where to place it at first and eventually decided to have it sticking out at around a 45 degree angle from the top of the container. I also found a black plastic washer which will match nicely with the bulb base.

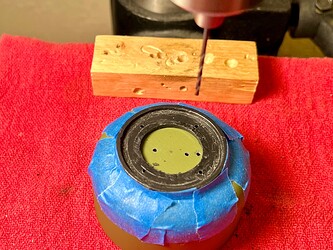

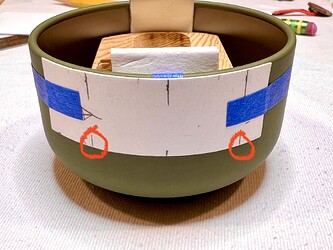

I drilled the switch hole and the ancillary light hole right below it. For the ancillary light hole, I also used a round file to make it nice and circular.

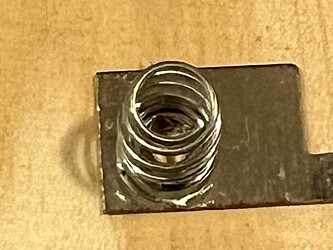

I needed to go to the hardware store in order to get a nut that would fit the switch since none that I had would. The only nut they had, which I was thankful they had one, was pretty big. So I hammered it into a piece of wood and filed it down.

With the tubing and black plastic washer, the switch is very secure.

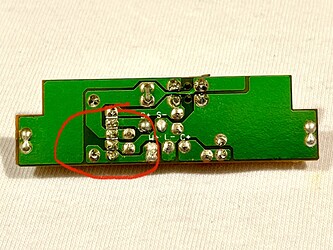

I had to file down the top of ancillary light PCB in order to position the green LED next to the hole. With the board in the plastic tubing, I’m able to slightly adjust it the up and down once the switch is screwed into place. And as you can see, I’m able to position it perfectly. Plus, the plastic tubing presses nicely against the hole.

Next up will be the main LED and more work on the wood body.

![]()