yep ![]()

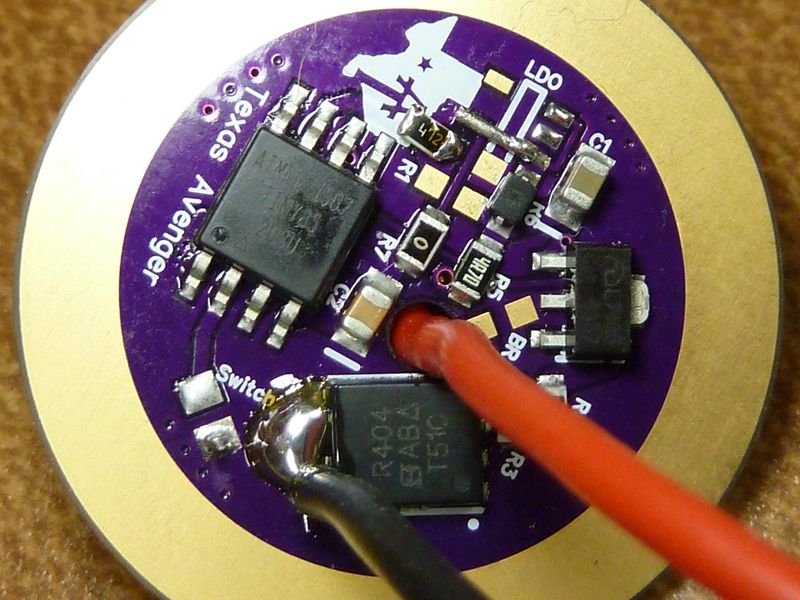

But honestly this very driver was not built by me.

Due to lack of experience and tools have to start with smth more simple and so while I was working on Convoy S8+triple Nichia 21C+preparing driver and flashing custom firmware one local guy was helping me with that pre-meteor driver for SRK.

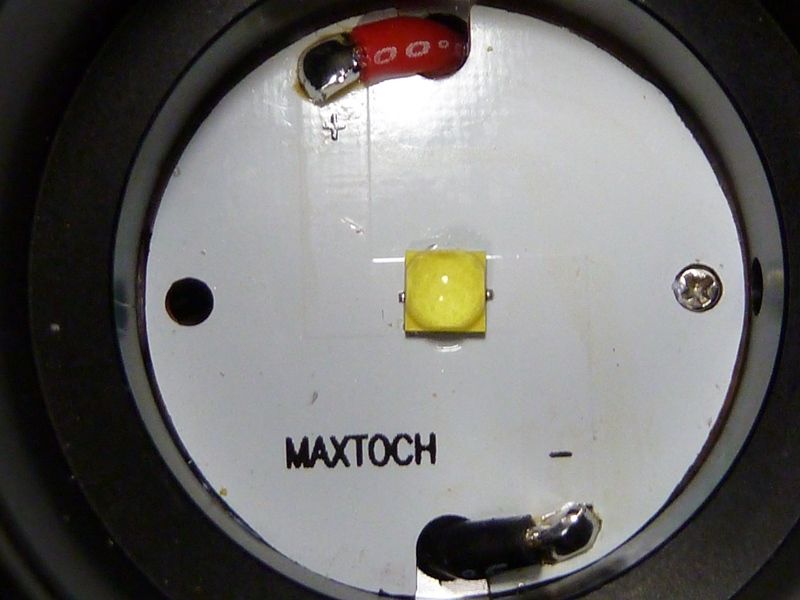

I’ve already removed some extra solder while soldering contact rings.

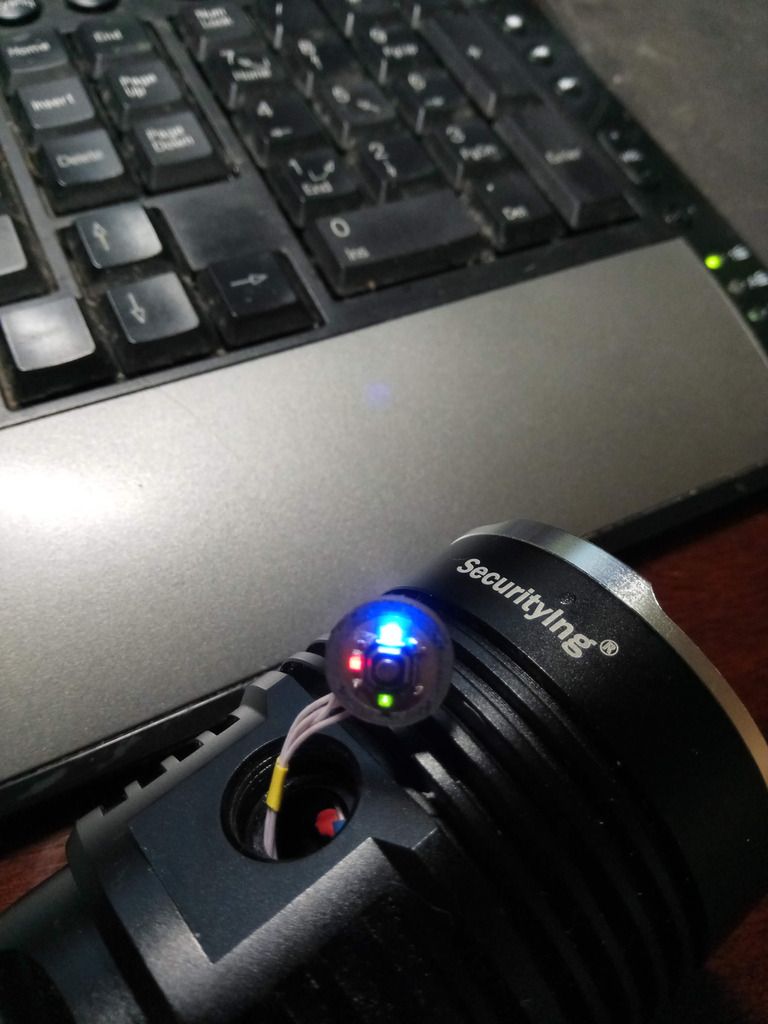

There is still some work left - waiting for half transparent button. Must be ready in 2-3 days.

Now I’m looking for some good single 26650 host with side button to put XHP50 led and similar driver

and still not decided whether I need to order one more SRK clone (besides Q8 ![]() ) for modding. Wanna insert the same pre-meteor driver and 4 XHP50 (or 4 XHP35).

) for modding. Wanna insert the same pre-meteor driver and 4 XHP50 (or 4 XHP35).