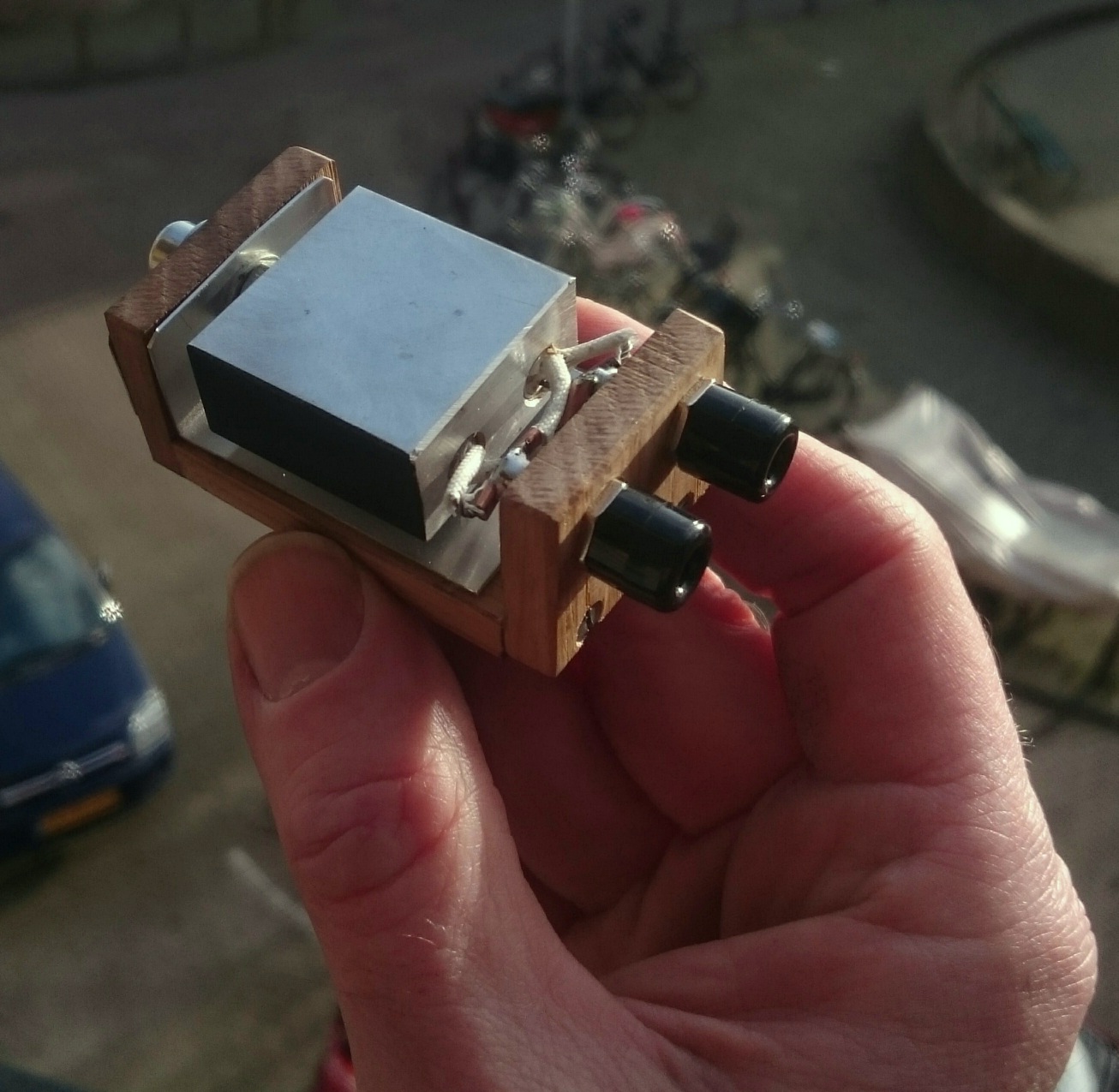

In this thread sac02 showed how he made his heatblock using these ultra-cheap 3D printer heaters to make a heat block for reflow soldering, after a suggestion of mrheosuper.

So I made my version.

Of course not everything went smooth, i.e. notice the many not so straight angles ;-) , and one heating element was DOA, I'm glad I tested them first before I hammered them (bit of arctic silver) into the 6mm holes that I made in the aluminium block. Come to think of it, tip: drill the 6mm holes through the block to the other side so you can remove an element when it is dead (I did not do that so I just hope they keep working)

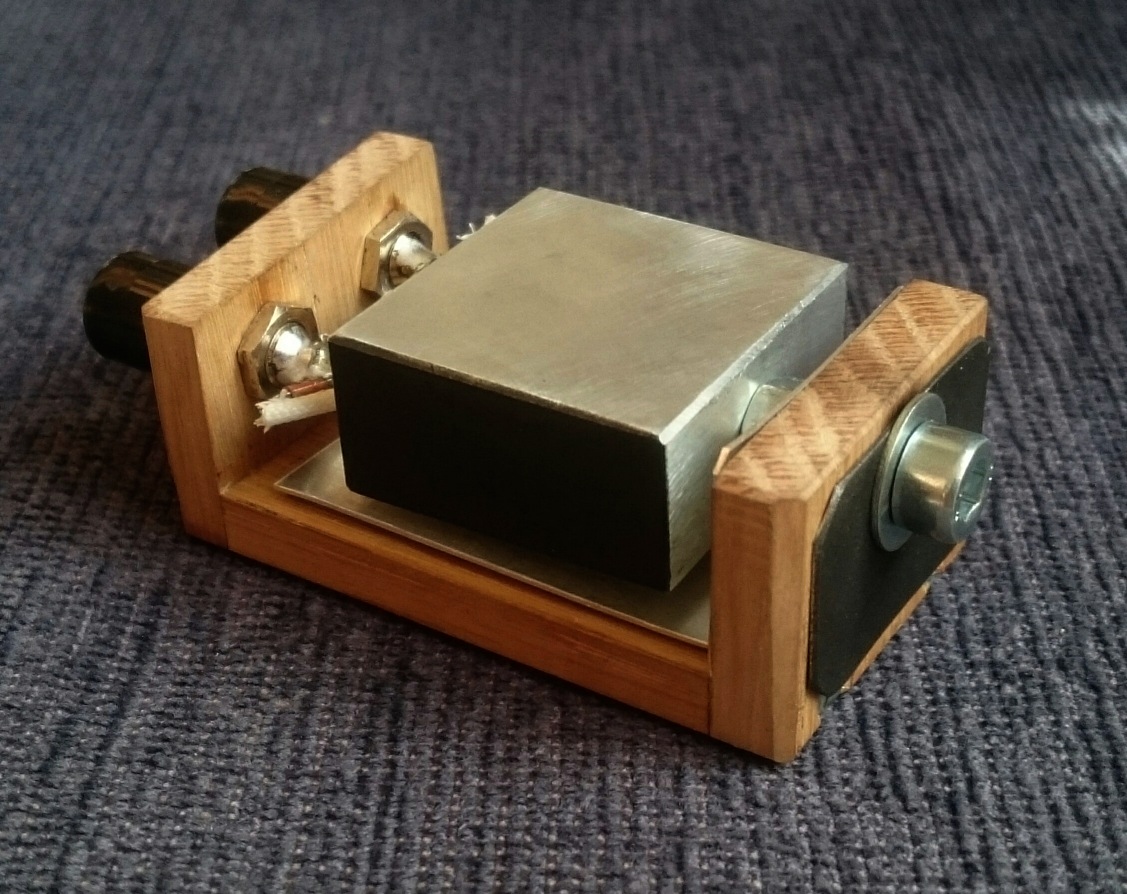

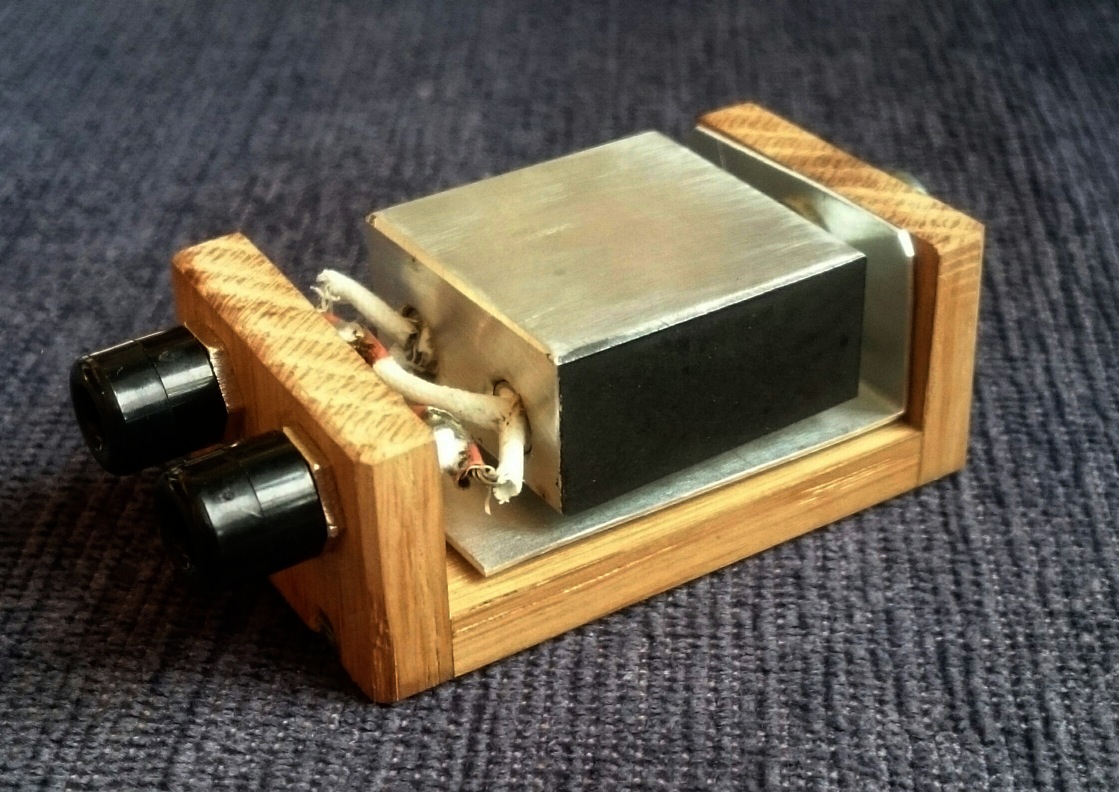

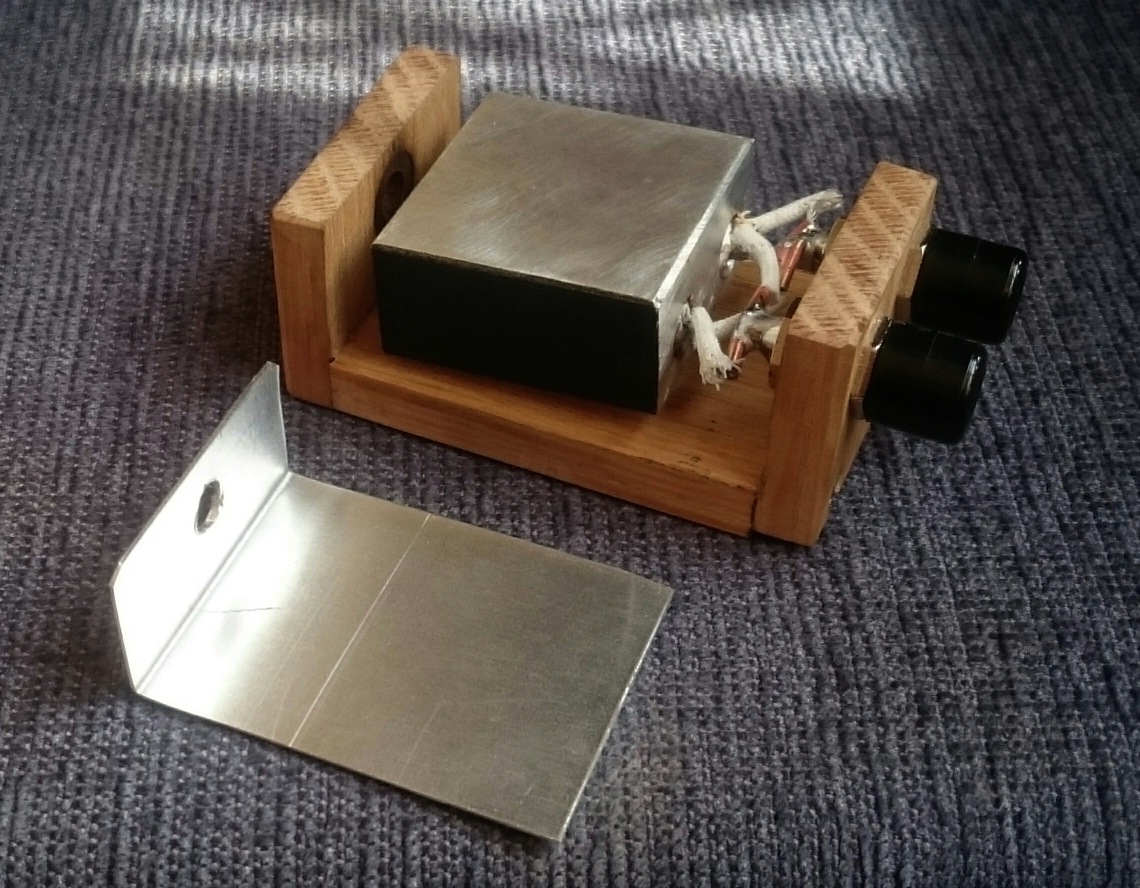

And I first had no aluminium shield against the wood. And after the block had been 240 degrees C. for a while, the wood began to blacken where the (free hanging on one bolt) block was bolted into the wood. I should not have gone for one M5, it passes way too much heat, two a bit longer M2 bolds on both sides would have been smarter. And I may had better avoided wood altogether probably. So the heat shield is not so much for radiation shielding, but to spreaden the heat that comes via the bolt. Now at 240 degrees the wood carbonises a lot slower, but I expect it to gain character fast! ;-)

You can see where the wood had burned, therefore I added aluminium on both sides from the bold.

I made the sides of the block black with engine paint so I can measure the temperature with my (cheap but works well) infrared thermometer.

So here the block is 234 degrees steady state, which is a great reflow temperature, it takes 18 minutes to get there. This is at 3.2 A and about 6V at the block (the two elements are parallel, the leads are long and not so thick), so about 19W. When I place a 20mm Noctigon board on the block, the temperature fast drops 10 degrees, the temperature then recovers in about a minute, sounds fine to me.

At the outside of the bolt I attached a bit of black aluminium too to wick away some more heat, and that becomes disturbingly hot too (let's see how long the wood lasts ![]() ):

):

I'm pretty happy with this thingy, it works well for what I want it for (reflowing leds on boards, and reflowing components on driver boards, I may add a video of a reflow later).

I would change a few things here and there next time, and who knows how shortlived these cheap heating elements are, but at least it was fun to make :-)

________________________________________________

edit: a one-handed (thus a bit un-handy) video of a XP-L reflow. I noticed that it is hotter than my usual reflow block, I may lower the temperature a bit next time: