Update 10/04/14: some highlights found in this thread:

- Post #96 is ROD911's impressions of a simple emitter swap to MT-G2 using stock driver, stock amps (post #114 is beamshots I can't view?)

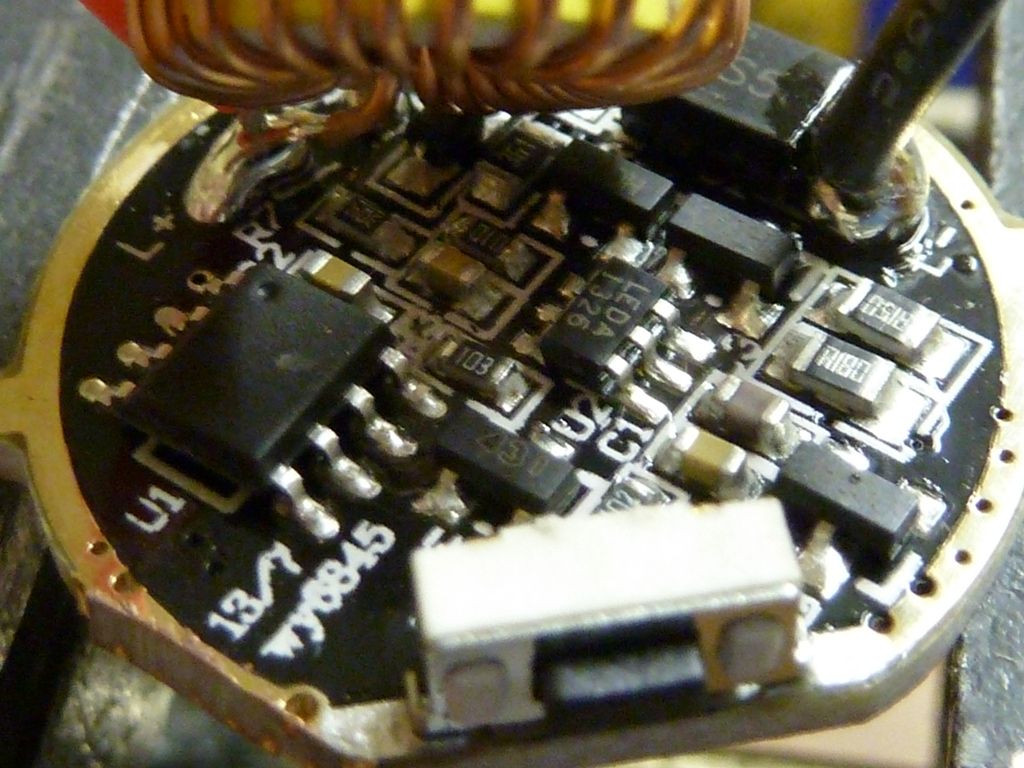

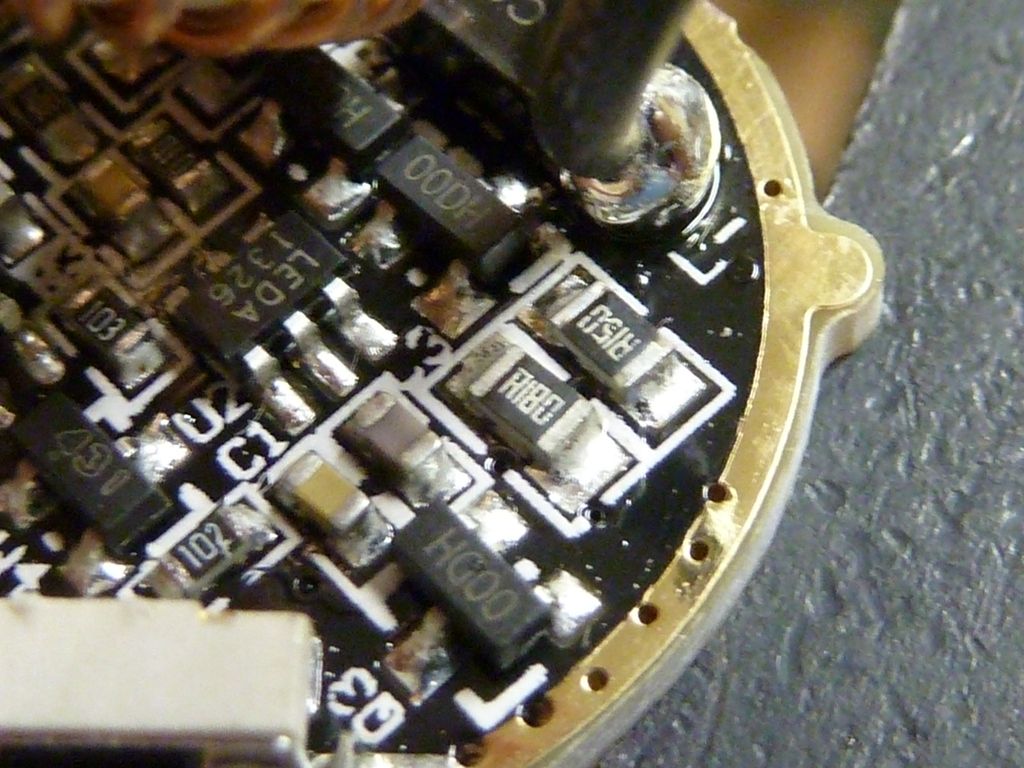

- Post #118 - some useful info on resistors

- Post #126 - R100 result with a MT-G2, UCLp lens

- Post #144 - details on DMM wire leads used to measure amps

- Post #145 - aoeu's impressions/results on MT-G2, and grinding down the head (pic posted at post #184)

- Post #166 - details on the MaxToch 26 MCPCB used in a Y3

- Post #169 - fellfromtree's impressions, mods

- Post #262 - grantman232 posted some nice beamshots featuring 2 mod'ed Y3's - de-domed XM-L2 and a MT-G2

Just want to add grantman321 and aw73 seem to be having a similar issue of measuring only about 2.05A at the tail on one cell (should be 2.45 - 2.52A or so). My gut says it's the measurement methodology, but aw73 seems to be using proper leads on his DMM. Really dunno - could be a driver issue as wight pointed out, buck drivers are tricky on single cells. Not sure if anyone else has similar experiences.

Update 9/27/14: Post #166 shows details on a Y3 mod using the new MaxToch 26 mm MCPCB

Following is a breakdown of the Yezl Y3 by pictures. Hope this answers some questions. First couple of pics are from a previous bought/sold Y3, most are new.

Shown with the classic HD2010:

Tailcap:

HD2010 on left, Y3 on right:

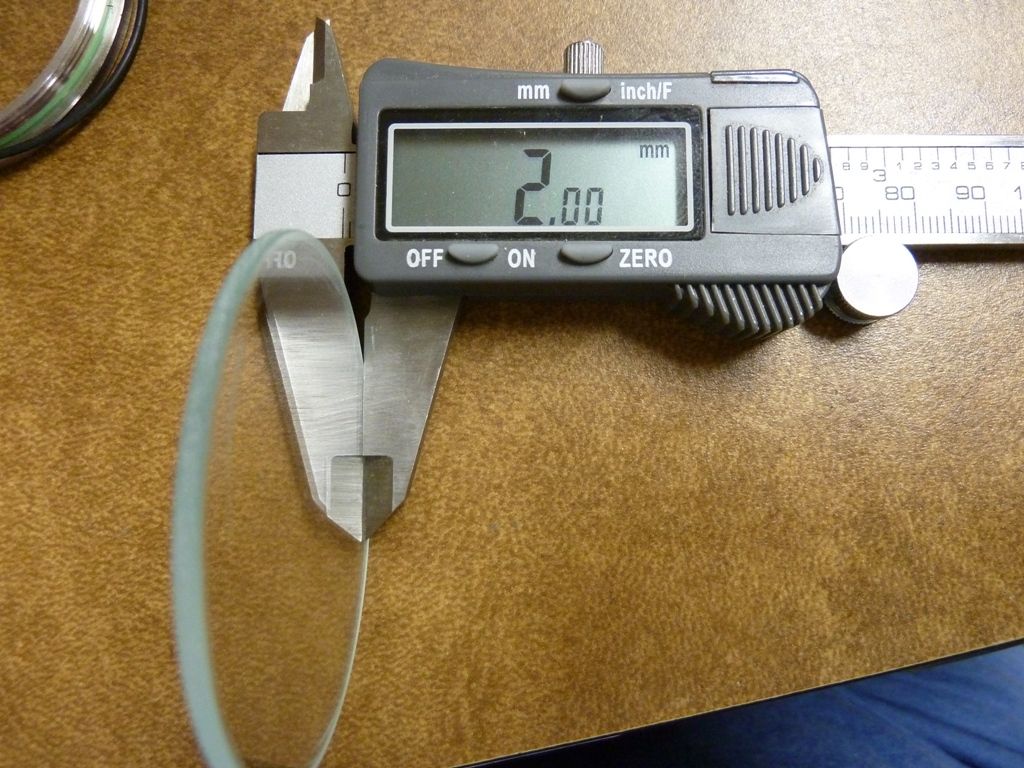

All my measurements were done more precisely than shown. I simply left the setting on the caliper and tried to show what I was measuring in the photo:

I.D. is what matters. Y3:

HD2010:

The front stack - the black o-ring is a little over sized, so you have to keep an eye on it wne re-assembling, that it doesn't squeeze out:

lens diameter:

Thickness:

Diameter of stock MCPCB:

shelf width:

Dab of grease used, stock:

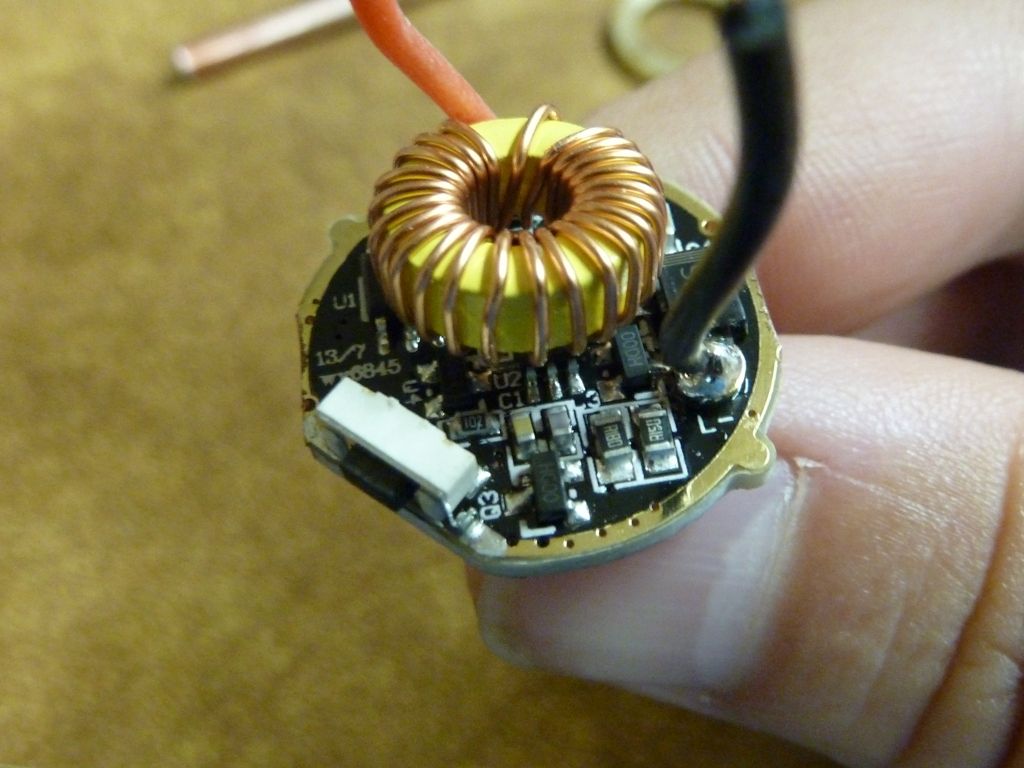

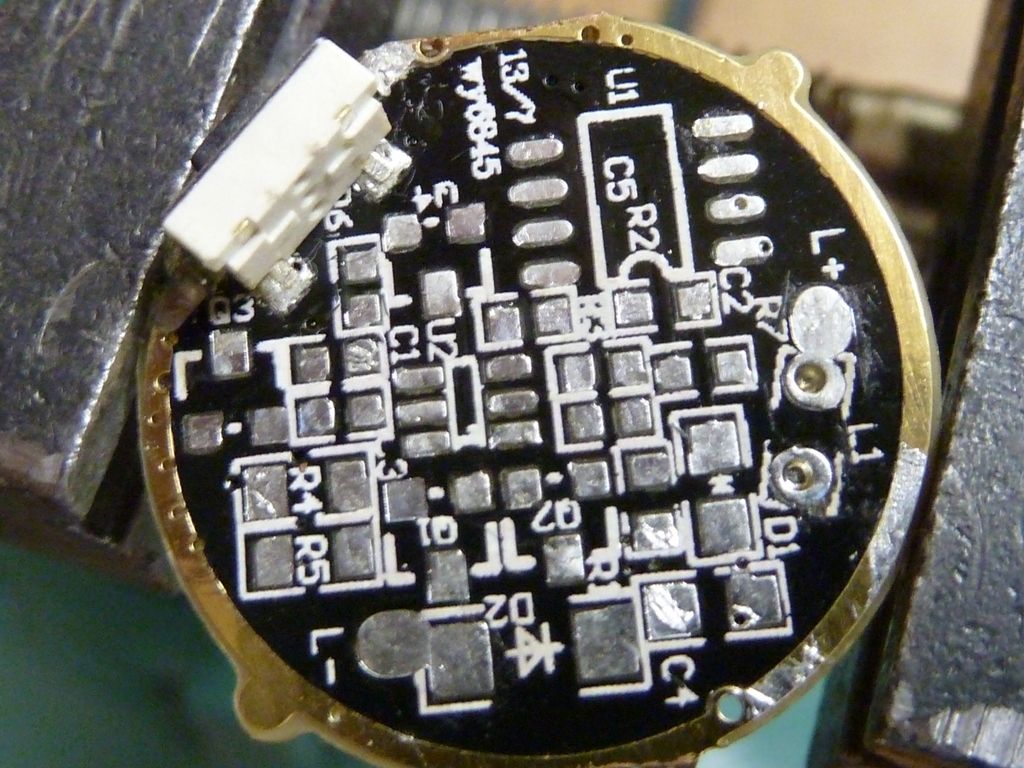

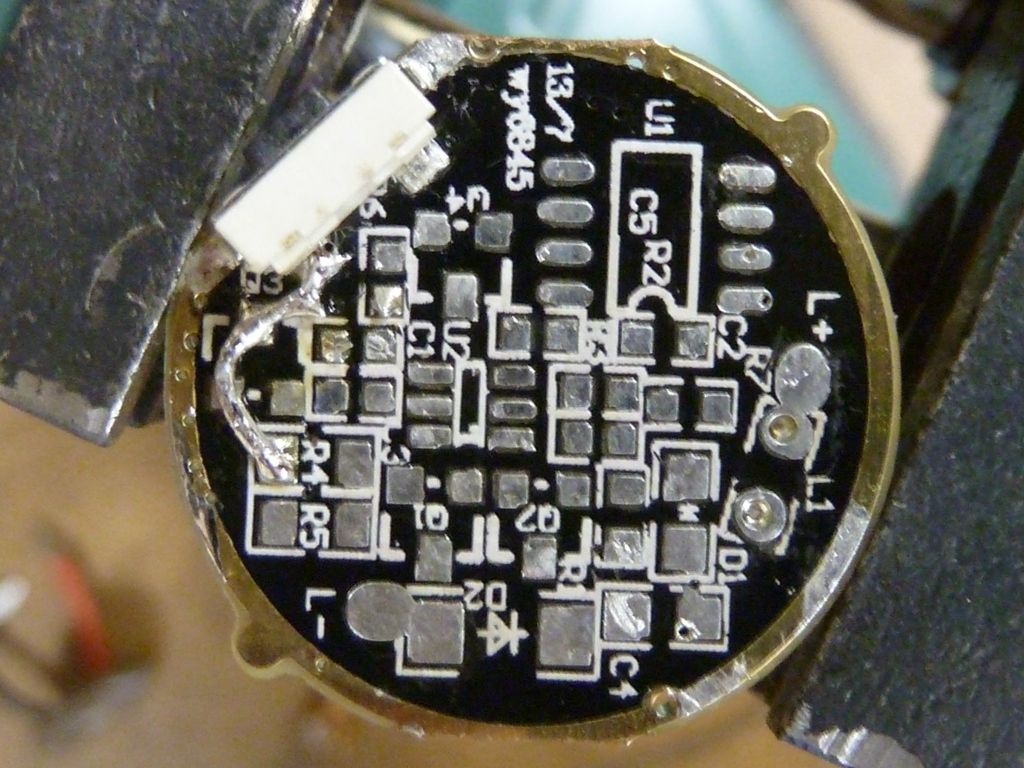

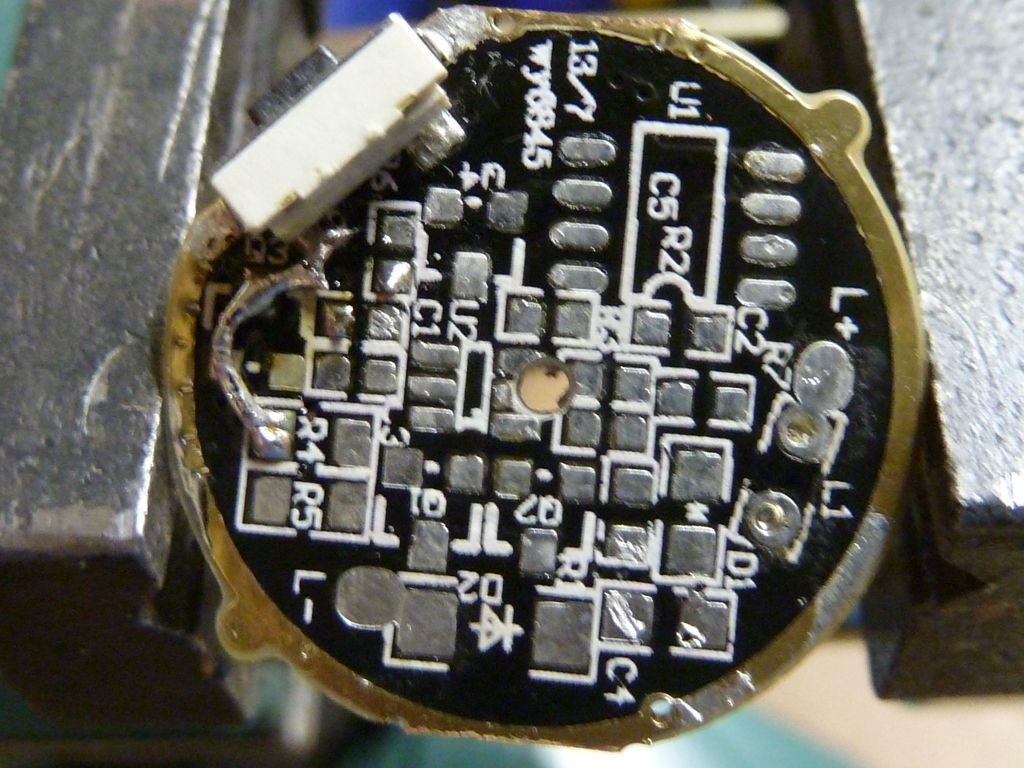

Driver, battery side:

Driver diameter:

This is the shelf thickness (~). Measured at the LED wire holes using a tool, and marking where it's flush. It's nice and thick:

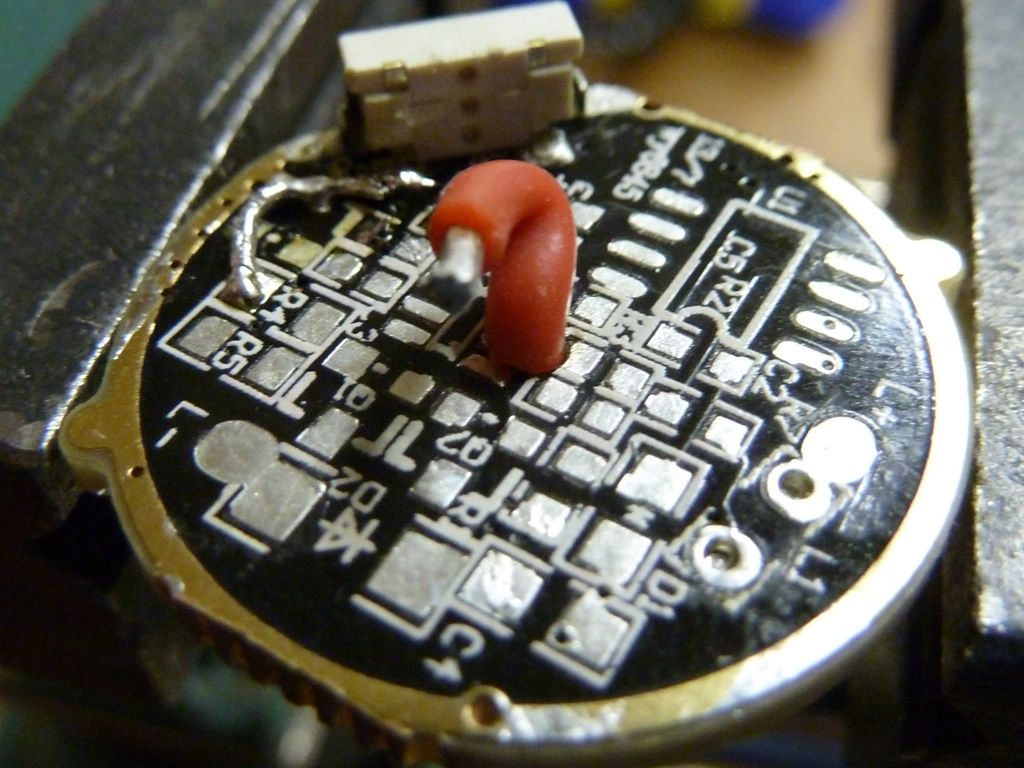

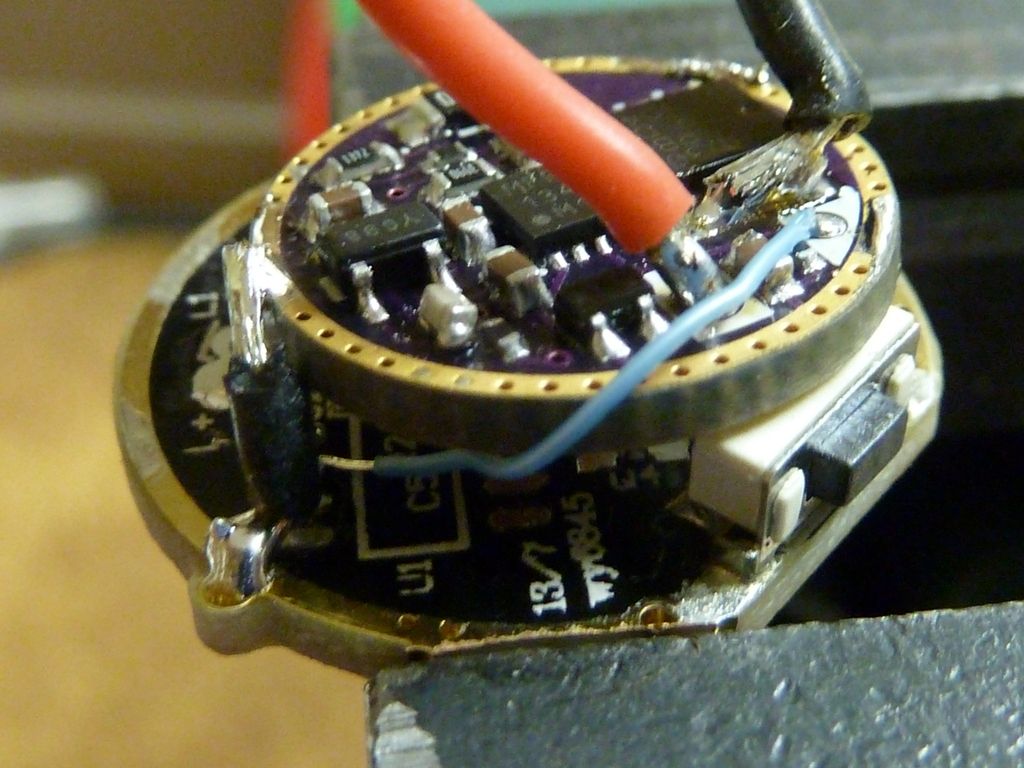

Stock driver:

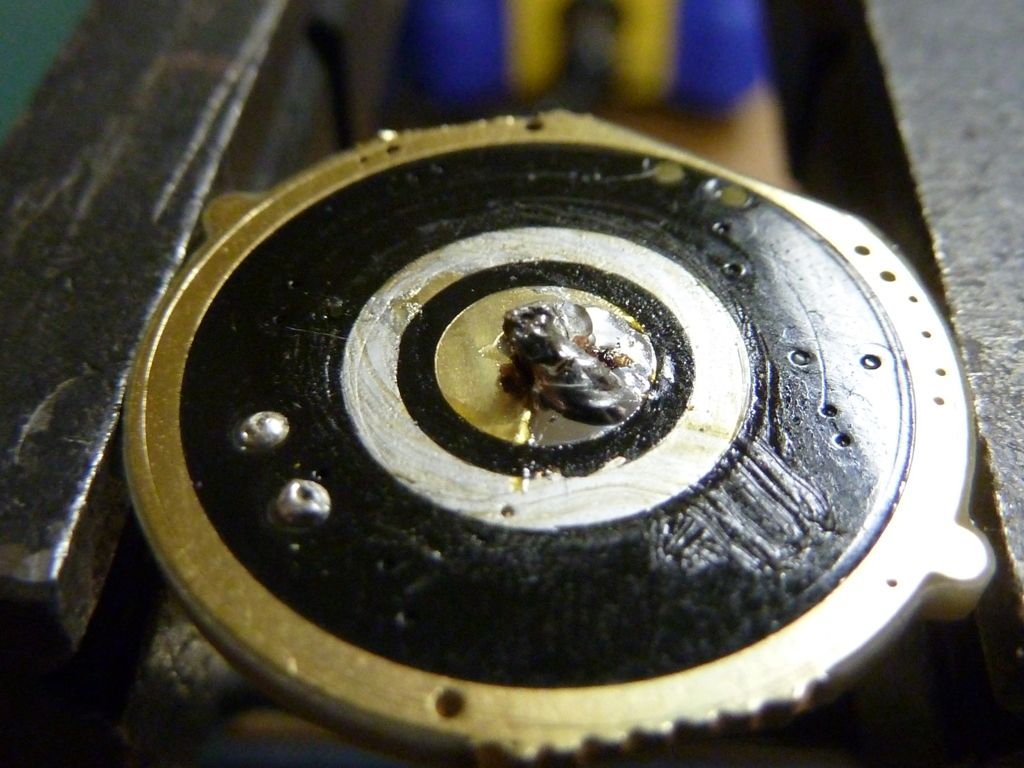

Nice smooth shelf top, but is it really flat as it looks?

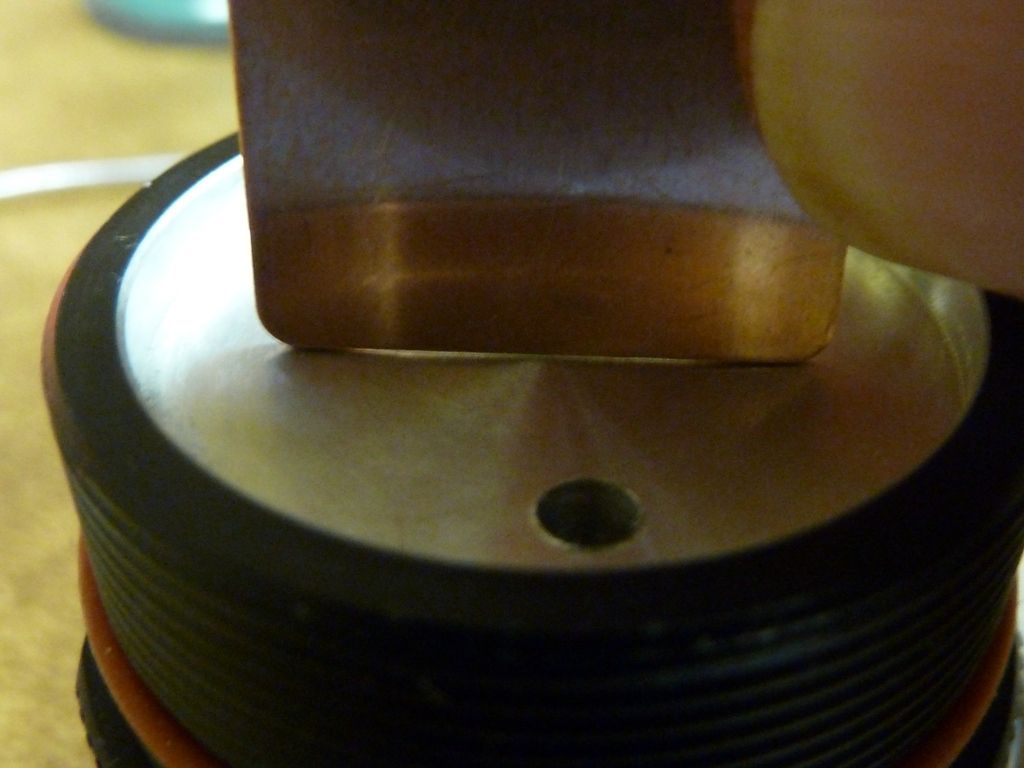

Inside of shelf top is not so flat - has an inny:

Tail assembly:

The switch is not typical rectangular, but looks more like a tactical (fwd) but really is a reverse clicky. It has not writing on it but appears to be good quality:

Ooops, maybe not so flat. I tried other flat surfaces besides this copper piece and all seem to indicate the same pattern. I also testes the copper piece on other flat surfaces and did not notice the unevenness as shown here. Hhmm - I did build a 5.7A Y3 before and didn't notice this, but I didn't look for it as I do now.

I can try sanding by hand, but don't think it will help much. If anyone has suggestions to get this flat, please post.

Update 08/03/2014:

Here it is after the sanding I did. Not much improvement:

I used quite a bit of thermal grease and didn't see any squeeze out, so thinking there's still a significant gap.

Modding the Yezl Y3

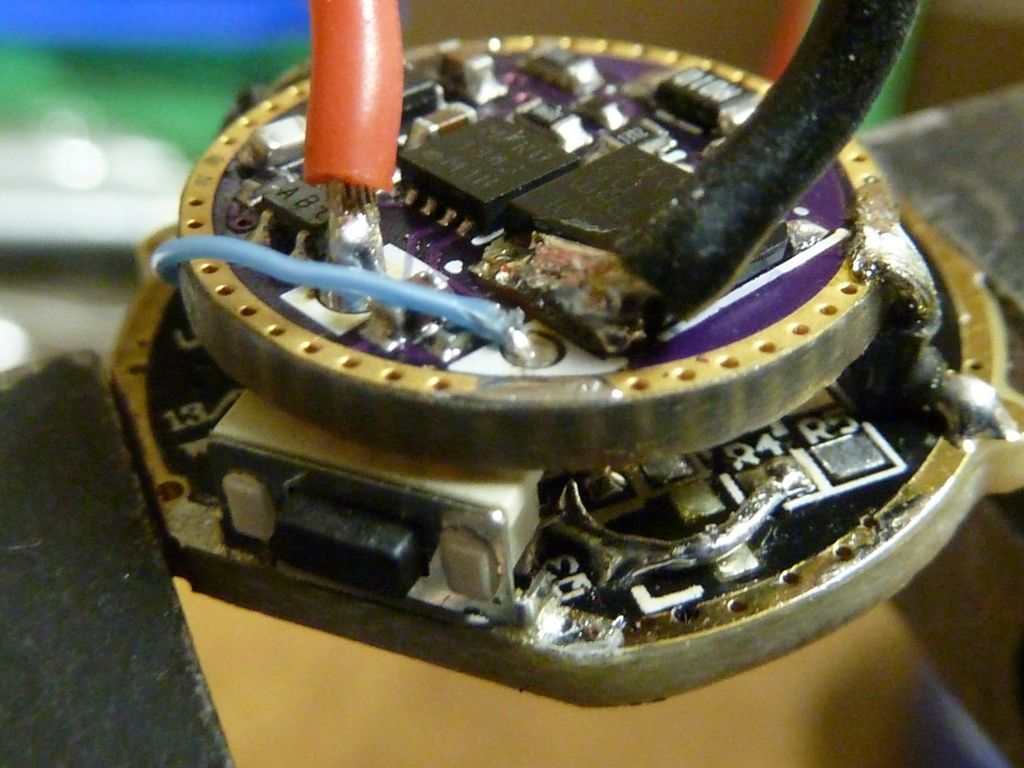

Stripped stock driver (hot air used, then cleaned up with solder wick and isop. alcohol):

Added a jumper (upper left) to ground one end of the e-switch, and bring grounds to extra pads on the stripped board:

Drilled a hole through the PCB to route a + 20 AWG wire through (avoid small traces on the stock board):

Here's the wire in place:

Soldered from below:

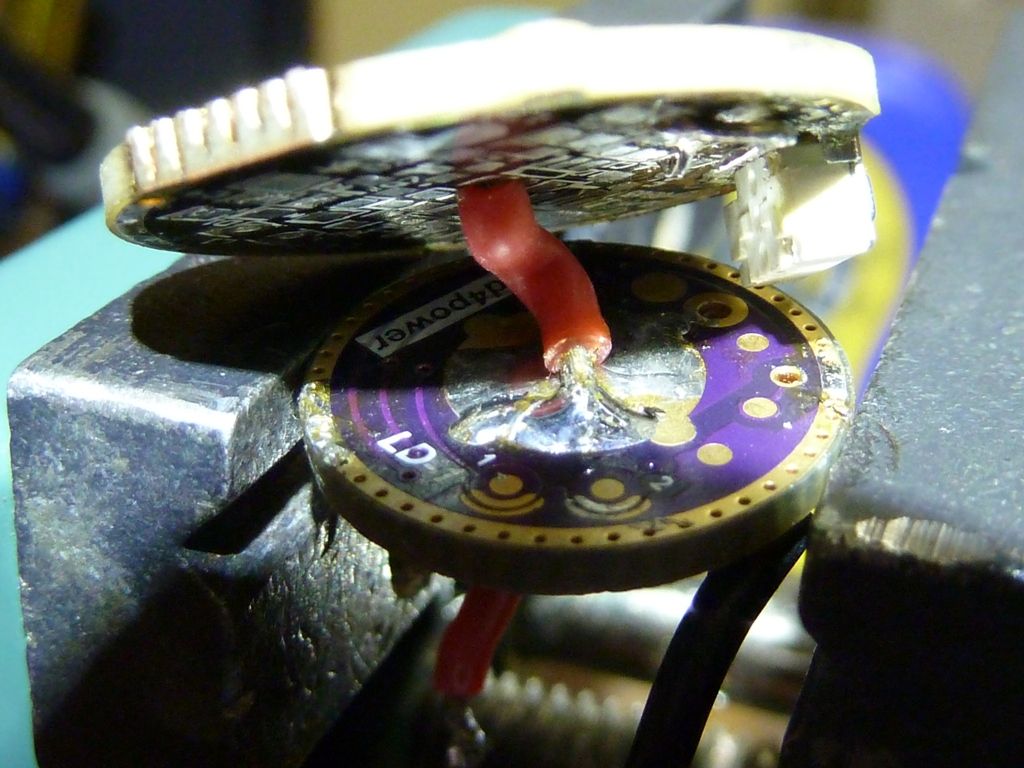

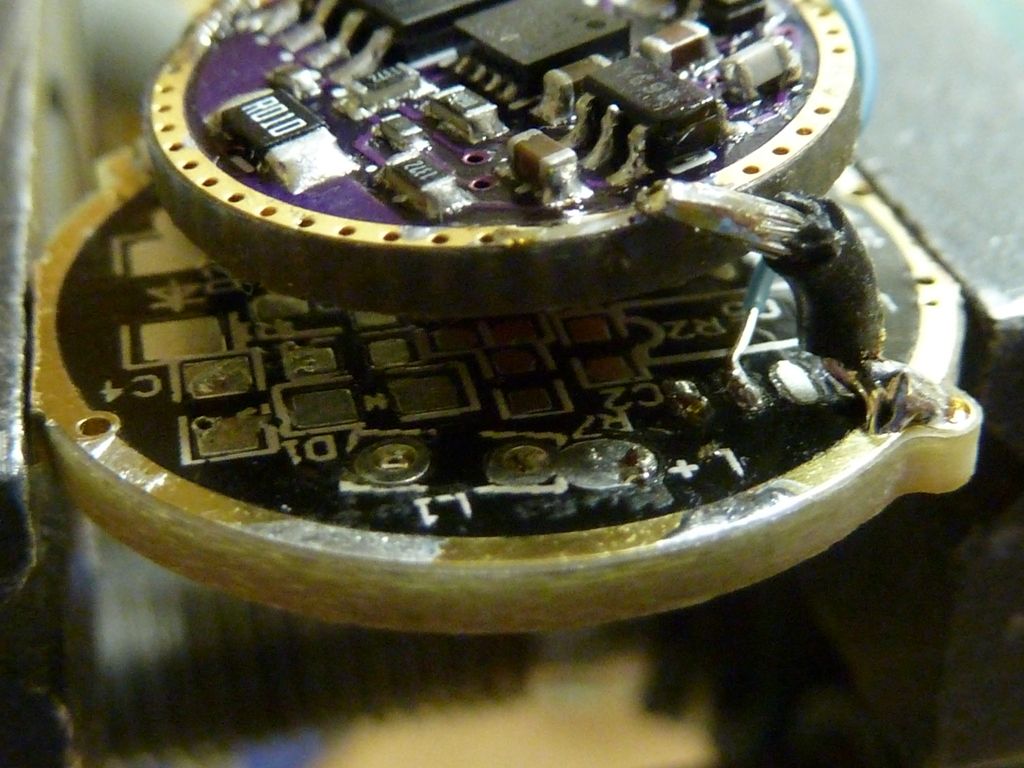

Soldered up to the LD-1:

Two ground connections and the e-switch wire added from a MCU pad on the original stock driver to the e-switch input of the LD-1 driver:

View of the 22 AWG wired up spring:

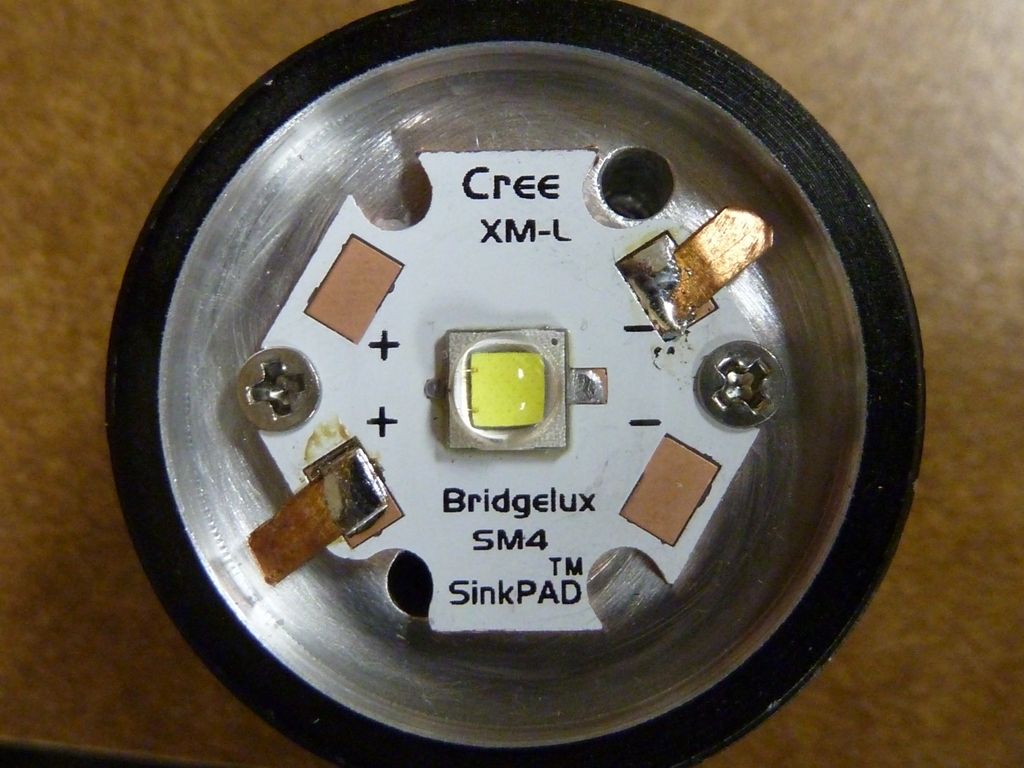

The XM-L2 U2 1D on a 20mm SinkPAD, drilled/tapped holes for screws, add copper sheet metal tabs to extend wires outward:

Wired up to the 20 AWG wires:

Stock one piece LED alignment piece. I cut out the sides to make room for the tabbed connections:

Pure speculation, but if a MT-G2 at 15A is less efficient than 5 XM-L2's running at the same power (ie watts), doesn't that mean more power gets converted to heat? So, maybe even worse? Think you got a room heater there, forget hand warmer.

Pure speculation, but if a MT-G2 at 15A is less efficient than 5 XM-L2's running at the same power (ie watts), doesn't that mean more power gets converted to heat? So, maybe even worse? Think you got a room heater there, forget hand warmer.